Trinity Packaging Corp. is a privately held family business. Founded in 1917 as a paper bag converter, Trinity Packaging installed its first plastics extruder in 1979. Since then it has expanded its focus to include the flexible films market, enabling the company to offer a wider variety of products. The company has three plant locations in the U.S. that manufacture plastic products for a broad base of American customers in a wide range of industries.

At our plant in Pueblo, CO, we convert blown film into retail plastic bags. Our converting facility has a variety of specialized equipment to create bags with complex features, such as multi-colored printing or air-tight closures. We started this project with the goal of improving the efficiency of our wicket style bag making machines.

Improving efficiency in bag making machines

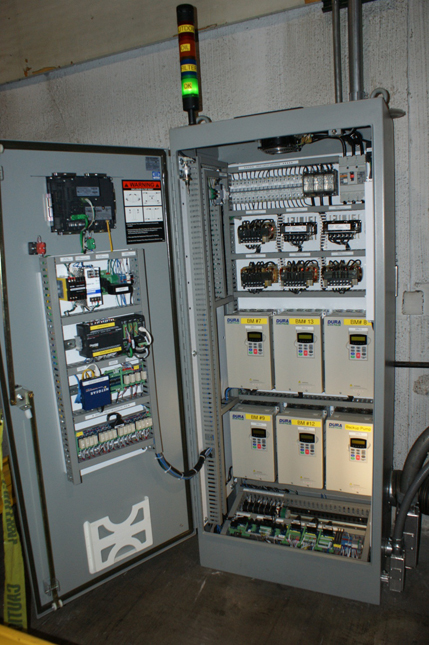

The five wicket style bag making machines we operate use aluminum arms with vacuum holes in them to grab the bag after it has been cut. The vacuum holes then stack the bag on a conveyor. The Roots blowers we use to develop the required vacuum pressure are multi-stage blowers with several fans stacked together (Image 1).

Our goal was to cut costs and increase efficiency by improving the vacuum system. When we started the project, each bagging machine required two centrifugal blowers, each using a 10HP motor running at full rated speed, in order to create the required vacuum.

The reason we needed two blowers per machine was because the pumps sucked much of the petroleum waste released into the air as a result of the bag cutting and sealing process. As more residue built up on the blowers, the vacuum suction would weaken, making the blowers very inefficient. Since we couldn't accurately monitor the machines to assess the amount of residue buildup, we had to have two blowers running all the time to make sure there would be sufficient vacuum.

Moreover, we couldn't risk shutting down the blowers when the machines weren't running, because the amount of residue buildup would often cause the pumps to lock up and trip the control system at startup. Furthermore, the motors always ran at full speed even when the process didn't need that level of vacuum.

Image 1: These pumps create the required vacuum pressure for our wicket style bag making machines.

Improving maintenance and total cost of ownership

In an effort to improve efficiency and overall operations, we conducted a pilot project on one of the machines. The first step was to install AutomationDirect? ProSense vacuum pressure transmitters at the inlet of the pumps.

We selected the ProSense vacuum pressure transmitter because it's specifically designed to monitor relative system pressure for hydraulics and pneumatics applications. Easy to install, this compact pressure transmitter provided reliable pressure indication from its ceramic sensing element. We installed five transmitters in total that measure the actual vacuum pressure at the pump and send an analog signal to the input card in the machine's AutomationDirect DirectLOGIC DL06 PLC.

Alarms are programmed to notify us if the pressure rises too high; this tells us the filters need to be changed. If the pressure goes too low, another alarm is triggered telling us the pump has lost its belts. One ProSense temperature transmitter monitors the drive enclosure to turn the cooling fans off and on.

A potential problem discovered on the first day

The day we switched to the new system, it looked like we had a problem with the controls because one line was showing very high pressure. We looked at the machine and found one of the vacuum hoses had come off and sucked several bags in. It immediately notified us of a problem that would have gone undetected by our previous system.

Moreover, improved monitoring helped us to create a precise cleaning schedule based on data collected by the transmitters. This enabled us to use the second blower as a backup blower, instead of having it run all the time. As a result we significantly reduced our overall equipment and maintenance costs.

Installing drives provides big savings

Next, we paired one of our blowers with a Durapulse variable frequency drive from AutomationDirect, and monitored the results for approximately six months.

As mentioned earlier, each of our blowers is connected to multiple vacuum arms, and these arms are periodically removed for cleaning. After being cleaned, the blowers run more efficiently, so less power is needed from the motors. However, without a drive, there wasn't any way to reduce the blower motor speed.

By adding a drive, the motor speed can now be adjusted according to the amount of vacuum required, which increases energy efficiency significantly. When everything is clean the motor only needs to run at half speed. Based on readings from the vacuum transmitter, the drive increases the motor speed automatically as the arms get dirtier to maintain the required vacuum pressure.

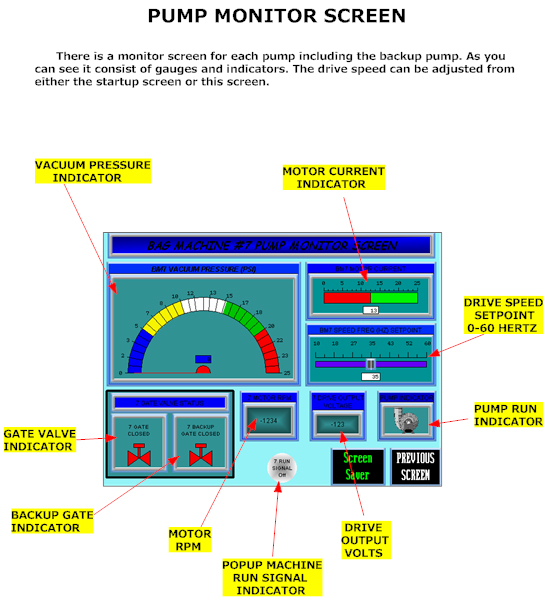

The result from our initial undertaking was so impressive we decided to expand our pilot to all our wicket style bag making machines (Image 2).

Image 2: New blower motor drives dramatically reduce energy costs by allowing motors to run at less than full speed, depending on machine requirements.

Adding advanced HMI

Better pressure and vacuum monitoring along with the variable speed motor drives supplied useful data, so we added an AutomationDirect C-more HMI touchscreen panel to our control system to display and help interpret this data. An Ethernet card in the DL06 PLC communicates the data to our C-more touchscreen HMI. Our new HMI enables the data can be monitored either on the panel or remotely, which also helps us respond quickly to any possible issues.

Our drives communicate directly with the HMI using the Modbus protocol. This was the first time we used Modbus, so we needed a bit of help from the AutomationDirect support team. One of the reasons we chose AutomationDirect products was the economical price of its products, but we were pleasantly surprised to learn that a great price can be coupled with superior technical support. The AutomationDirect support team was very responsive and helped us get up and running quickly.

By using the Modbus protocol, we were able to eliminate a lot of wiring and associated costs because we didn't need to buy many analog sensors to send current, rpm and other readings to the C-more HMI, as this information is simply transmitted in digital form each drive to the HMI.

Image 3: This HMI screen displays information from a variable speed drive and associated valving, allowing more precise monitoring and control of machine operation.

Valuable information at our fingertips

It was very easy to program the C-more HMI using the Windows-based graphical editor. For example, we simply entered setpoints for low and high pressure to create alarm parameters. When an alarm is triggered, it automatically appears on the screen, and an email is sent.

We also monitor the amount of hours each pump is running; an alarm tells us when to change the oil to increase both operating efficiency and the lifespan of the machine. If any drive fault, belt failure or pressure fault occurs-the PLC opens the backup gate and turns the backup pump on. The system then emails us the event tag from the HMI. The best part is this happens instantly and automatically, allowing production to continue as if the event never occurred.

When we started the project, I saved images and specifications of every AutomationDirect component that we used in the system from AutomationDirect's website. I then converted this information to bitmaps, and imported them into the C-more HMI. This has been a great tool, because now if we need information on any part, we can pull it up immediately on the plant floor from the HMI touchscreen.

Dramatic savings

Our new automation system has greatly reduced the amount energy we use and cut the number of blowers needed for regular operations in half. This has significantly decreased our overall operating costs on these machines. As energy prices continue to rise, we have been able to offset those increases from the energy we save by running the blowers only as needed to maintain sufficient vacuum pressure.

The old system needed two 10HP motors running at full rated speed for the two centrifugal blowers to successfully operate each machine. By removing the need for a second full-time blower on each machine, we have eliminated approximately one week of maintenance for each pump on the five machines we operate. The load on the remaining motor has also been reduced because the drive can adjust motor speed to deliver only the amount of vacuum that is needed to hold the bags in place.

As a result, we have seen a dramatic drop in energy usage after installing the automation system. We recently hired an outside firm to perform an energy audit and calculate the overall savings we can expect. Using a total annual operating cost of $49,000 per year for the wicket bag making machines as a basis, the audit showed we can expect a $13,000 a year savings in operating costs.

We have been so pleased with the success of our improved vacuum system for our wicket style bag making machines that we are now developing a project to use the newest AutomationDirect Programmable Automation Controllers to upgrade our older equipment in other parts of the plant.

Benefits

1. Over 25 percent decrease in energy and operations costs

2. Motors can now operate at reduced speed

3. Advanced monitoring and control eliminates the need for second blower

4. Easy HMI programming and alarming

5. Modbus protocol reduces wiring and labor costs