Lowara has developed an innovative function to rid domestic water systems of troublesome air pockets within the pump housing quickly and cost effectively with the Air Purge function on its new Lowara Ecocirc domestic hot water circulator.

Lowara has developed an innovative function to rid domestic water systems of troublesome air pockets within the pump housing quickly and cost effectively with the Air Purge function on its new Lowara Ecocirc domestic hot water circulator.

The Ecocirc can be set to purge air from within the system and then return to its previous working pattern automatically by simply turning the control dial. The integrated air purge functionality is key to helping installers to maintain the efficiency of domestic hot water recirculation pumping systems.

Giorgio Menegazzi, Xylem's Global Product Manager for circulators, comments: Integrating maintenance functions into the product design can save both time and money on the upkeep and repair of pumping equipment. Purging air from a recirculation pump is one such procedure and our built-in Air Purge mode is leading the way for pump Manufacturers worldwide who want to make their products as user friendly and technologically advanced as possible.

To activate the Air Purge function, the installer must simply turn the control dial to the full stop position for five seconds before returning it to the required hydraulic working-point indicator. This will automatically begin the Air Purge cycle and once completed, the pump will reinitiate pumping at the hydraulic working-point that has been specified.

The Ecocirc Air Purge cycle will run the pump at maximum speed for a predetermined length of time, followed by a shorter period of minimum speed. This cycle will be repeated ten times in order to flush air pockets from the circulator housing.

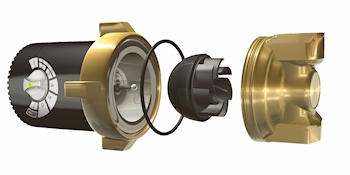

The Lowara Ecocirc boasts a market leading electronically commutated spherical motor which has only one moving component the impeller/rotor unit. This means that the pump can perform to its maximum capabilities after any period of inactivity.