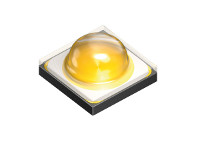

The new Oslon Square LED is designed to maintain color and lumen consistency even at temperatures as high as 135°C, enabling developers to use the emitters in enclosed indoor SSL products where high temperatures are typical.

Osram Opto Semiconductors has announced new members of the 3×3-mm Oslon Square family of LEDs that the company asserts are capable of reliable operation at extended junction temperatures. The new versions can be reliably driven at higher currents, allowing solid-state lighting (SSL) developers to deliver more cost-effective lamps or luminaires for indoor applications where enclosed operation can lead to high ambient temperatures.

Osram is characterizing and binning the new Oslon Square LEDs at 85°C because that temperature is more typical than 25°C that has been the typical level used for characterization in the industry for data sheets. Higher binning temperature, however, is no longer new as many manufacturers now follow that path. But Osram said that a new device architecture allows its new square LEDs to operate at even higher junction temperatures.

"With our new conversion technology, we can produce significantly thinner converter layers," said Ivar Tangring in SSL product development at Osram. "The thinner layers better dissipate the heat, thus enabling the higher temperatures in the LED." Presumably, the thinner converter layers refer to the phosphor application on the LED.

Specifically, the new chip architecture has resulted in a better thermal resistance specification of 3 K/W relative to 3.8 K/W in the prior generation products. Improved thermal resistance allows the LEDs to be driven at 1.8A, up from 1.5A. While the thermal resistance achievement is notable, it's not unique in the industry. The Philips Lumileds Luxeon TX LEDs announced in October carry the same spec, and in fact Lumileds had delivered that performance level in the prior-generation Luxeon T LEDs.

Ultimately, the ability of LEDs to operate reliably at higher temperature can reduce SSL system cost in multiple ways starting with higher efficacy. SSL developers can use fewer LEDs at higher drive currents to deliver the lumen package required in an application. "This luminous efficacy, meaning the ratio of luminous flux to applied electrical power, helps our customers to significantly optimize the price/performance ratio of their luminaire solutions," said Tangring.

Osram specifies typical efficacy at 100 lm/W for a 3000K LED operated at 85°C. The higher temperature further means that SSL product designs will need simpler, less costly thermal management designs. Indeed, Osram said that the new LEDs will deliver consistent lumen and color maintenance for more than 50,000 hours when operated at 135°C.

Osram said that the new LEDs are currently undergoing LM-80 testing and will pass the 3000-hour mark by the end of the year. That's a significant milestone for a next-generation LED product in which the prior-generation LEDs have been tested to LM-80 because the Energy Star certification process for SSL products using the second-generation products can commence at 3000 hours. The full 6000 hour test results will be available in the spring of 2014.

Osram for now says the LEDs will be offered over the range of 2700–5000K CCTs. The family will have a minimum CRI of 80 with a typical value of 82. For now it's not clear whether the company will also offer higher-CRI versions of the product.

About the Author Maury Wright is editor of LEDs Magazine and Illumination in Focus.