With the unchanging trend of falling LED prices, chip manufacturers are constantly improving LED chip production process and technologies to lower costs. Semiconductor equipment company GT Advanced Technologies (GTAT) has developed Hydride Vapor Phase Epitaxial (HVPE) system that can replace nGaN and uGaN growth process in MOCVD. In the future, LED chip manufacturers can add HVPE systems to speed up epitaxy growth rates. Compared to adding MOCVD to expand production capacity, using HVPE system can increase production capacity and help LED chip manufacturers cut up to 25 percent of costs.

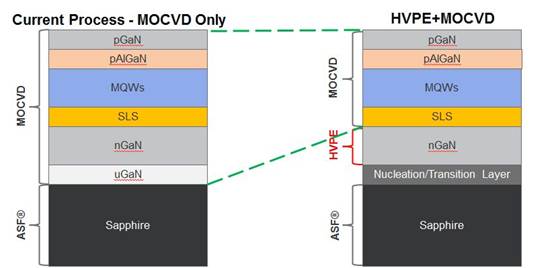

Comparison between MOCVD and HVPE production. (LEDinside/ GTAT)

In May 2013, GTAT announced it will be using HVPE patent from Soitec Phoenix Labs, a subsidiary of Soitec. HVPE technology is characterized by fast nGaN and uGaN growth speeds that can lower production costs. The technology uses GaCl3 as a precursor which is 10 times cheaper than TMG used in MOCVD. HVPE system can produce nGaN and uGaN at a much faster rate than MOCVD. Hence LED chip manufacturers can use HVPE system to expand production capacity.

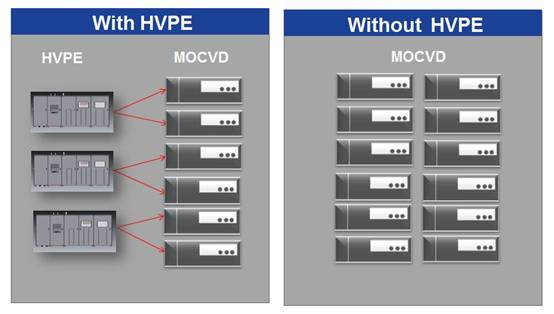

Comparison between HVPE and without HVPE. (LEDinside/ GTAT)

A single HVPE production capacity is equivalent to two MOCVD, GTAT explained. For example, in the past a LED chip manufacturer with 12 MOCVD equipment might need to add another 12 machines to double its production capacity, but by using HVPE system only six HVPE system equipment is required to replace nGaN and uGaN growth process. At the same time, this allows MOCVD machines to focus on other substrate layer growth to expand production capacity, which can help LED chip manufacturers obviously lower equipment costs.

HVPE system can fulfill sapphire substrate GaN scalability and lower production cost. It is estimated HVPE system can reduce more than 80 percent of precursor costs, and at the same time increase production volume of the costly MOCVD production process, and reduce LED chip manufacturers cost by as high as 25 percent. The HVPE system is expected to hit the markets by 2H14.