A bearing is a machine element that constrains relative motion between moving parts to only the desired motion. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts.

| Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts. The term "bearing" is derived from the verb "to bear";a bearing being a machine element that allows one part to bear (i.e., to support) another. The simplest bearings are bearing surfaces, cut or formed into a part, with varying degrees of control over the form, size, roughness and location of the surface. Other bearings are separate devices installed into a machine or machine part. The most sophisticated bearings for the most demanding applications are very precise devices; their manufacture requires some of the highest standards of current technology. | |

| ball bearing |

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Evolution of Bearing

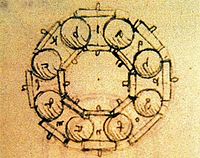

| | The invention of the rolling bearing, in the form of wooden rollers supporting, or bearing, an object being moved is of great antiquity, and may predate the invention of the wheel. Though it is often claimed that the Egyptians used roller bearings in the form of tree trunks under sleds,this is modern speculation. The earliest recovered example of a rolling element bearing is a wooden ball bearing supporting a rotating table from the remains of the Roman Nemi ships in Lake Nemi, Italy. The wrecks were dated to 40 AD. Leonardo da Vinci incorporated drawings of ball bearings in his design for a helicopter around the year 1500. This is the first recorded use of bearings in an aerospace design. However, Agostino Ramelli is the first to have published sketches of roller and thrust bearings.An issue with ball and roller bearings is that the balls or rollers rub against each other causing additional friction which can be prevented by enclosing the balls or rollers in a cage. Henry Timken, a 19th century visionary and innovator in carriage manufacturing, patented the tapered roller bearing in 1898. The following year he formed a company to produce his innovation. Over a century the company grew to make bearings of all types, including specialty steel and an array of related products and services.

|

| Drawing of Leonardo da Vinci Study | |

| | |

| Early Timken tapered roller bearing |

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Bearing Glossary

ABEC - The Annular Bearing Engineering Committee

ACBG - Airframe Control Bearings Group of the Society of Automotive Engineers

Age Hardening - Material hardening by aging

Aging - Change in the properties of a material that occurs at moderately elevated temperatures after hot working or heat treatment.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Types

There are many different types of bearings.

| Radial Bearings Thrust Bearings Y-Bearings, Track Bearings Needle Bearings | Cylindrical Bearings | Sleeve Bearings | Spherical Bearings | Ball Bearings | Linear Bearings | Roller Bearings | |

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Service Life

| | The service life of the bearing is affected by many parameters that are not controlled by the bearing manufactures. For example, bearing mounting, temperature, exposure to external environment, lubricant cleanliness and electrical currents through bearings etc. Fluid and magnetic bearings Fluid and magnetic bearings can have practically indefinite service lives. In practice, there are fluid bearings supporting high loads in hydroelectric plants that have been in nearly continuous service since about 1900 and which show no signs of wear. |

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Maintenance and Lubrication

| Many bearings require periodic maintenance to prevent premature failure, although some such as fluid or magnetic bearings may require little maintenance. Most bearings in high cycle operations need periodic lubrication and cleaning, and may require adjustment to minimise the effects of wear. | |

| | Bearing life is often much better when the bearing is kept clean and well-lubricated. However, many applications make good maintenance difficult. For example bearings in the conveyor of a rock crusher are exposed continually to hard abrasive particles. Cleaning is of little use because cleaning is expensive, yet the bearing is contaminated again as soon as the conveyor resumes operation. Thus, a good maintenance program might lubricate the bearings frequently but never clean them. |

| Some bearings use a thick grease for lubrication, which is pushed into the gaps between the bearing surfaces, also known as packing. The grease is held in place by a plastic, leather, or rubber gasket (also called a gland) that covers the inside and outside edges of the bearing race to keep the grease from escaping. | |

Written by Nicolas Yang