Don Stookey knew he had botched the experiment.One day in 1952,the Corning Glass Works chemist placed a sample of photosensitive glass inside a furnace and set the temperature to 600 degrees Celsius.At some point during the run,a faulty controller let the temperature climb to 900 degrees C.Expecting a melted blob of glass and a ruined furnace,Stookey opened the door to discover that,weirdly,his lithium silicate had transformed into a milky white plate.When he tried to remove it,the sample slipped from the tongs and crashed to the floor.Instead of shattering,it bounced.

The future National Inventors Hall of Fame inductee didn't know it,but he had just invented the first synthetic glass-ceramic,a material Corning would later dub Pyroceram.Lighter than aluminum,harder than high-carbon steel,and many times stronger than regular soda-lime glass,Pyroceram eventually found its way into everything from missile nose cones to chemistry labs.It could also be used in microwave ovens,and in 1959 Pyroceram debuted as a line of space-age serving dishes:Corningware.

The material was a boon to Corning's fortunes,and soon the company launched Project Muscle,a massive R&D effort to explore other ways of strengthening glass.A breakthrough came when company scientists tweaked a recently developed method of reinforcing glass that involved dousing it in a bath of hot potassium salt.They discovered that adding aluminum oxide to a given glass composition before the dip would result in remarkable strength and durability.Scientists were soon hurling fortified tumblers off their nine-story facility and bombarding the glass,known internally as 0317,with frozen chickens.It could be bent and twisted to an extraordinary degree before fracturing,and it could withstand 100,000 pounds of pressure per square inch.(Normal glass can weather about 7,000.)In 1962 Corning began marketing the glass as Chemcor and thought it could work for products like phone booths,prison windows,and eyeglasses.

Yet while there was plenty of initial interest,sales were slow.Some companies did place small orders for products like safety eyeglasses.But these were recalled for fear of the potentially explosive way the glass could break.Chemcor seemed like it would make a good car windshield too,and while it did show up in a handful of Javelins,made by American Motors,most manufacturers weren't convinced that paying more for the new muscle glass was worth it—especially when the laminated stuff they'd been using since the'30s seemed to work fine.

Corning had invented an expensive upgrade nobody wanted.It didn't help that crash tests found that"head deceleration was significantly higher"on the windshields—the Chemcor might remain intact,but human skulls would not.

After pitches to Ford Motors and other automakers failed,Project Muscle was shut down and Chemcor was shelved in 1971.It was a solution that would have to wait for the right problem to arise.

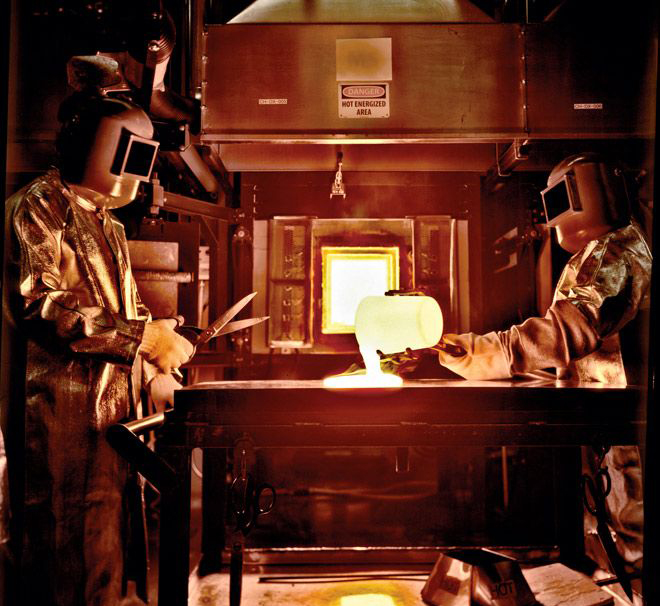

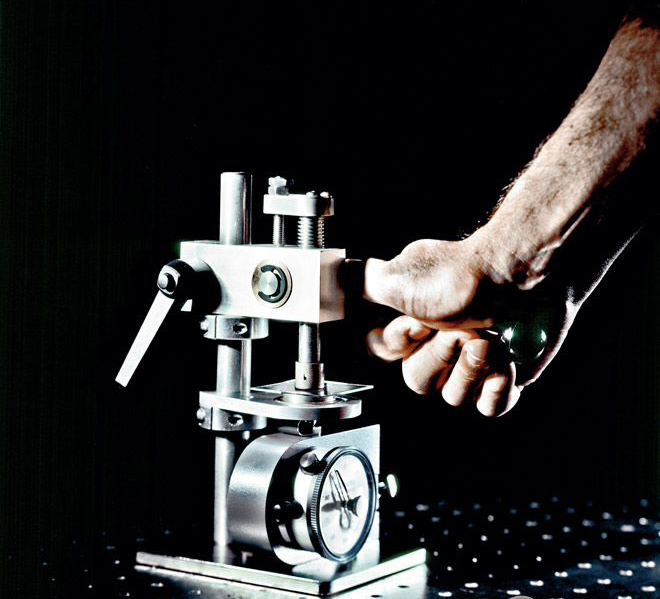

When glass is hardened and strengthened it can withstand huge amounts of force from a lever press.

Photo:Max Aguilera-Hellweg

From above, Corning's headquarters in upstate New York looks like a Space Invaders alien:Designed by architect Kevin Roche in the early'90s,the structure fans out in staggered blocks.From the ground,though,the tinted windows and extended eaves make the building look more like a glossy,futuristic Japanese palace.

The office of Wendell Weeks,Corning's CEO,is on the second floor,looking out onto the Chemung River.It was here that Steve Jobs gave the 53-year-old Weeks a seemingly impossible task:Make millions of square feet of ultrathin,ultrastrong glass that didn't yet exist.Oh,and do it in six months.The story of their collaboration—including Jobs'attempt to lecture Weeks on the principles of glass and his insistence that such a feat could be accomplished—is well known.How Corning actually pulled it off is not.

Weeks joined Corning in 1983;before assuming the top post in 2005,he oversaw both the company's television and specialty glass businesses.Talk to him about glass and he describes it as something exotic and beautiful—a material whose potential is just starting to be unlocked by scientists.He'll gush about its inherent touchability and authenticity,only to segue into a lecture about radio-frequency transparency."There's a sort of fundamental truth in the design value of glass,"Weeks says,holding up a clear pebble of the stuff."It's like a found object;it's cool to the touch;it's smooth but has surface to it.What you'd really want is for this to come alive.That'd be a perfect product."

Weeks and Jobs shared an appreciation for design.Both men obsessed over details.And both gravitated toward big challenges and ideas.But while Jobs was dictatorial in his management style,Weeks(like many of his predecessors at Corning)tends to encourage a degree of insubordination."The separation between myself and any of the bench scientists is nonexistent,"he says."We can work in these small teams in a very relaxed way that's still hyperintense."

Indeed,even though it's a big company—29,000 employees and revenue of$7.9 billion in 2011—Corning still thinks and acts like a small one,something made easier by its relatively remote location,an annual attrition rate that hovers around 1 percent,and a vast institutional memory.(Stookey,now 97,and other legends still roam the halls and labs of Sullivan Park,Corning's R&D facility.)"We're all lifers here,"Weeks says,smiling."We've known each other for a long time and succeeded and failed together a number of times."

One of the first conversations between Weeks and Jobs actually had nothing to do with glass.Corning scientists were toying around with microprojection technologies—specifically,better ways of using synthetic green lasers.The thought was that people wouldn't want to stare at tiny cell phone screens to watch movies and TV shows,and projection seemed like a natural solution.But when Weeks spoke to Jobs about it,Apple's chief called the idea dumb.He did mention he was working on something better,though—a device whose entire surface was a display.It was called the iPhone.

Jobs may have dismissed green lasers,but they represented the kind of innovation for innovation's sake that defines Corning.So strong is this reverence for experimentation that the company regularly invests a healthy 10 percent of its revenue in R&D.And that's in good times and in bad.When the telecom bubble burst in 2000 and cratering fiber-optic prices sent Corning's stock from$100 to$1.50 per share by 2002,its CEO at the time reassured scientists that not only was Corning still about research but that R&D would be the path back to prosperity.

"They're one of the very few technology-based firms that have been able to reinvent themselves on a regular basis,"says Rebecca Henderson,a professor at Harvard Business School who has studied Corning's history of innovation."That's so easy to say,and it is so hard to do."Part of that success lies in the company's ability not only to develop new technologies but to figure out how to make them on a massive scale.Still,even when Corning succeeds at both,it can often take the manufacturer decades to find a suitable—and profitable enough—market for its innovations.As Henderson notes,innovation at Corning is largely about being willing and able to take failed ideas and apply them elsewhere.