In-situ metrology system maker LayTec AG of Berlin, Germany notes that it is known that some properties of gallium nitride (GaN)-based light-emitting quantum wells (QW) can be improved by using a-plane III-nitrides. However, during hetero-epitaxial growth on r-plane sapphire substrates, a-plane GaN layers are tensely strained in the growth plane, resulting in crack formation.

To achieve thick crack-free a-plane GaN buffer layers, low-temperature aluminium nitride interlayers (LT AlN IL) are used for strain engineering (M. Wieneke et.al., abstract book ICMOVPE 2012).

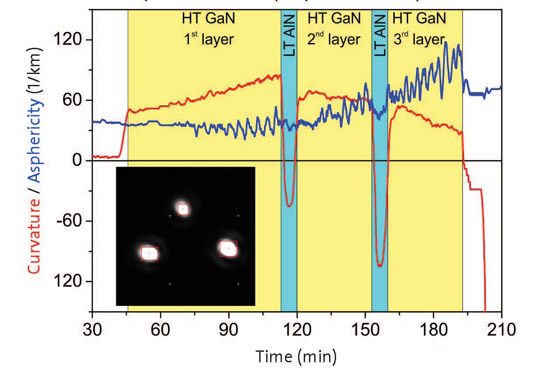

Picture: In-situ curvature measurements with EpiCurve TT AR of a-plane GaN samples containing two low-temperature AlN interlayers.

At the annual conference of the German Society for Crystal Growth (DGKK) last December, Matthias Wieneke of Otto-von-Guericke University in Magdeburg, Germany reported the impact of LT AlN IL on a-plane GaN films.

For the studies, his team applied LayTec's EpiCurve TT AR in-situ metrology system with advanced curvature resolution (AR). The tool uses three laser spots for curvature measurements (see the photo in the Figure) and, therefore, also provides information on wafer curvature asymmetry along two perpendicular directions (as is typical for a-plane III-N growth).

The in-situ curvature measurements are demonstrated in the Figure by a red line for (spherical) curvature and a blue line for curvature asphericity. During growth of the tensely strained a-plane GaN buffer layer, the curvature (red) increases, while it decreases after the insertion of LT AlN IL.

Thus, the interlayer reduces the tensile strain, as in the case of c-plane GaN growth. However, after the growth of the interlayers, the asphericity (Figure, blue) increases, indicating an increase in anisotropic strain. This anisotropy has been proven by subsequent ex-situ x-ray diffraction measurements (M. Wieneke et al., abstract book DGKK 2013).

“By measuring the aspheric bow component quantitatively with EpiCurve TT AR, our team obtains additional real-time information on a-plane layer formation,” comments Wieneke.