Korea University has been working to improve metal contacts on aluminium gallium indium phosphide (AlGaInP) light-emitting diodes (LEDs) [Dae-Hyun Kim et al, Jpn. J. Appl. Phys., vol55, p032102, 2016]. In particular, the research team added a tantalum diffusion barrier to lock in beryllium-alloy atoms in gold-based contacts on p-type GaP.

AlGaInP LEDs emit in the wavelength range from red down to green-yellow, used in traffic light lamps, automobile tail lamps, biotherapy, outdoor displays, and solid-state lighting.

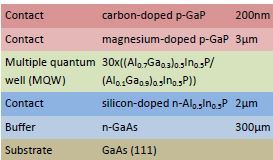

Figure 1: LED heterostructure.

The improved metal contacts are designed to overcome current crowding, which is a particular problem in p-type AlGaInP due to low hole concentrations. Platinum and palladium diffusion barriers have previously been shown to reduce specific contact resistivity to less than 10-6Ω-cm2 for gold-beryllium alloy contacts on p-type gallium arsenide (GaAs), annealed at 390°C for 30 minutes.

The heterostructures were grown by metal-organic chemical vapor deposition (MOCVD) on (111) GaAs substrates (Figure 1). The p-contact metal contact consisted of 130nm gold-beryllium alloy (1% weight Be), 20nm tantalum diffusion barrier, and 100nm gold. Devices without the tantalum barrier were produced for reference.

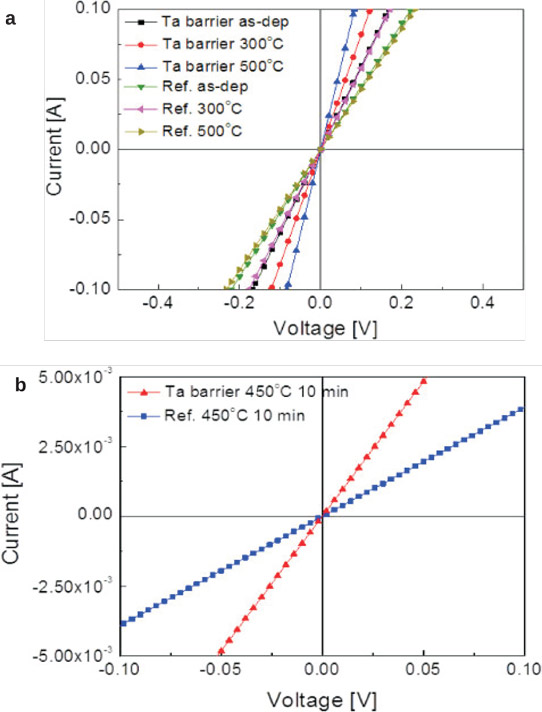

Figure 2: (Color online) (a) Current–voltage characteristics of gold-beryllium/gold (reference) and gold-beryllium/tantalum/gold contacts on p-GaP as deposited, and annealed at 300°C and 500°C. (b) Characteristics of contacts annealed at 450°C for 10 minutes.

Thermal annealing reduced the resistance of the tantalum barrier contacts, but degraded the performance of the reference samples without tantalum (Figure 2). The specific contact resistivity without annealing was 8.2x10-5Ω-cm2 and 3.4x10-5Ω-cm2 for the reference and tantalum-barrier contacts, respectively. After 500°C annealing, the tantalum-barrier resistivity improved by an order of magnitude – 2.8x10-6Ω-cm2, compared with degradation to 1.0x10-4Ω-cm2 for the reference sample.

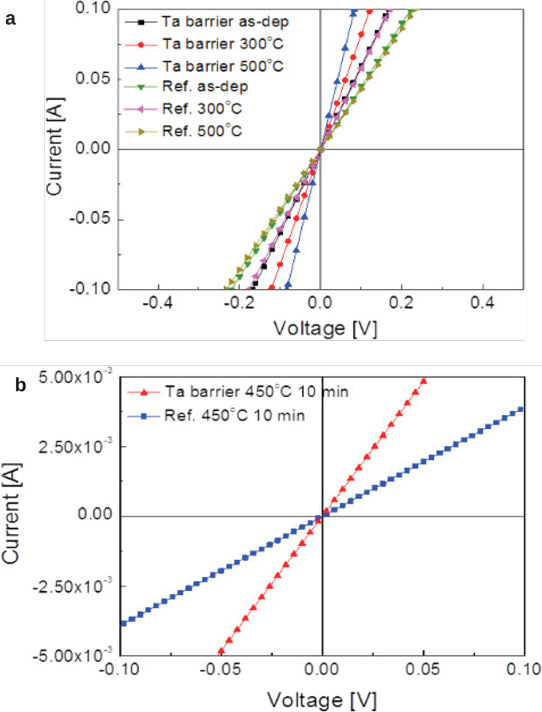

The LEDs with tantalum-barrier contacts that were annealed at 450°C for 10 minutes had a peak external quantum efficiency (EQE) of 14.0%, compared with 13.5% for annealed devices without a tantalum barrier (Figure 3). The researchers attribute the improvement to a lower forward voltage and higher reflectance in the 550-900nm wavelength range of the tantalum-barrier contact. The reflectance at 617nm was 92.8% for the tantalum-barrier contact, compared with 87.7% for the reference.

Figure 3: (a) Current–voltage characteristics and (b) external quantum efficiency (EQE) as a function of current of AlGaInP-based MQW LEDs fabricated with gold-beryllium/gold (reference) and gold-beryllium/tantalum/gold contacts annealed at 450°C for 10 minutes.

X-ray photo-electron spectroscopy (XPS) analysis suggested that the tantalum diffusion barrier reduced downward band bending, reducing the Schottky barrier height. Auger electron spectroscopy (AES) showed that the effect of the tantalum barrier was to block out-diffusion of the beryllium and encourage in-diffusion into the underlying GaP layer. Beryllium acts as an acceptor in GaP, increasing hole concentrations and reducing band bending near the surface.