Identifying the potential for running pumps as turbines originated because companies wanted to assess the impact on their systems if a pump stopped and went into reverse operation. One international pump manufacturer decided to examine the issue.

In many rural and remote areas of the world, access to a reliable power supply for the basic functions of light and heat still remains a major challenge. Having clean power supply capable of supporting electronic products such as computers and telecommunications is even further up the wish list for many communities.

Pumps as turbines

However, this situation could be coming to an end. An old and well-proven mechanical engineering technique that uses a centrifugal pump as a turbine to produce power is creating interest as it is both low cost and environmentally friendly. Known within the pump industry as a PaT (Pump as a Turbine), running a centrifugal pump in reverse rotation mode will, in certain conditions, create a turbine effect that can be exploited to generate power.

Operating a centrifugal pump as a turbine involves the liquid flowing from the discharge outlet to the suction inlet so that the impeller turns in the opposite direction. Should the head of pressure be high enough to overcome the breakaway torque of both the impeller and shaft, the torque can be employed to drive a generator, so the pump operates as a turbine.

Pump manufacturer KSB AG discovered that by calculating the turbine performance curves of pumps when running in reverse the behaviour of the pump running as a turbine was very good. This was because the energy output had the potential to be higher than the energy input used to run it as a pump.

Cost-effective alternative

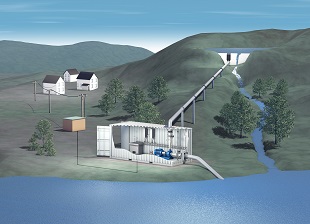

Encouraged by these findings, the company has been active in supplying PaTs to water supply companies as a cost effective alternative to employing hydro turbines to generate and recover energy for a number of years. In Europe it has over 3,000 PaTs in operation. KSB AG has also taken an active interest in applying the technology to generating power for small communities where there is no mains supply. The culmination of additional research and the refining of its existing technology have encouraged KSB to develop a small turnkey hydropower unit that offers remote communities a cost-effective method of generating off-line clean electricity (Figure 1).

Figure 1 -The Powerhouse offers remote communities a cost-effective method of generating off-line clean electricity.

Traugott Ulrich, KSB AG vice-president of start-up projects said: “For locations where there is a relatively constant water supply, but power supplies are unreliable or even non-existent, PaTs are a simple and economic approach to generating power. Through on-the-ground research in parts of the world where there is no mains power supply, we have been able to develop a standard PaT package that harnesses the energy of an available water supply and convert it into clean electricity. Most importantly, it can meet the widening electricity needs of remote and rural communities.”

The Powerhouse package

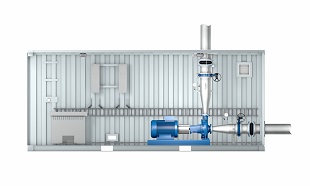

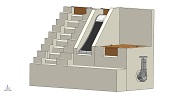

The Powerhouse comprises two main elements; a containerised hydropower unit (Figure 2) and an optional penstock for holding the water that drives the PaT (Figure 3). The Powerhouse contains the PaT, control electronics, converters and transformer that manage the power output. The penstock can be easily cast in concrete on site using the formwork kit supplied with the Powerhouse. Once constructed, the penstock and Powerhouse are connected by the water feed pipeline.

Figure 2 - The Powerhouse is a containerized hydropower unit.

Figure 3 - the penstock holds the water that feeds the PaT

Gravity flow is all-important to the functioning of the PaT and as a minimum the static head has to be 10 m above the Powerhouse. Depending on the type and size of the PaT, the static head can be as high as 640 m. In terms of distance from the penstock to the Powerhouse, the maximum recommended distance is 1800 m. The water pipeline between the penstock and the Powerhouse comes in two sizes, either 250 mm or 400 mm in diameter.

Ensuring that the water supply to the PaT is clean and free of debris is essential, and to this end the outlet from the penstock is fitted with a filter screen. Considerable thought has gone into this element, and the screen uses a highly innovative welded mesh structure that allows water to slide across the surface and drop through the 1.00 mm holes into a sump which feeds the pipeline supply to the PaT. All solids contained in the water flow slide off the surface and therefore do not penetrate or build up on the mesh surface, so it is self-cleaning.

The Powerhouse is a secure, containerised turnkey hydropower unit which delivers power in the range 30 kW – 750 kW. The control and monitoring panel is located on the interior. Due to its fully automated operating mode there is no need for the container to be opened other than for maintenance purposes. Given that the only wearing components will be the pump bearings and mechanical seal, and these have operating life spans of many years, maintenance requirements are very low.

Where it differs from other PaT systems is that the unit contains a customised self-controlled device that addresses two major challenges that have held back the development of the technology. The first challenge in small hydropower systems is where the generator unit is designed to run off-grid. In this scenario it is usual to employ a synchronous generator with a permanent magnet, which is expensive. The alternative approach involves using an asynchronous generator, which is basically a motor. The drawback to this option is that an asynchronous generator will not generate any electricity when it is turned, because it needs power, such as a small diesel generator set, to get it running.

KSB AG has addressed both challenges, the result being that its Powerhouse unit delivers an effective and efficient answer that removes the costly synchronous generator option, and also solves the problem of starting up the asynchronous generator. Start-up is performed by a battery-operated single small electrical control device that gives only a marginal amount of power to the asynchronous generator when it is required. Ulrich explains: “As an example, if you are running a 30 kW generator off-grid it may need as much as 27 kW to kick-start the generator. Our electronic control device is programmed to know exactly when to deliver a specific amount of power to kick-start the generator and uses a very small amount of power. This way, we have removed the need for a diesel generator set. Thus, the Powerhouse does not need any external electrical supply to make it work.”

Pumps in reverse

It is the pump running in reverse and acting as an asynchronous generator that is the all-important component of the Powerhouse. KSB AG has selected three different pump types that are best suited to this application, these being the Etanorm, the Omega single stage horizontal split case pump and the high pressure Multi-Tec horizontal ring section pump. These are all approved for turbine operation and are readily available throughout the world. When a pump is run as a turbine it will take approximately one third more in-flow so higher torque has to be taken into account, and it is for this reason that Omega and Etanorm Multi-Tec pump models are offered for locations where higher flows and pressures are encountered. The Omega can accept a head of up to 250 m and the Multi-Tec up to 640 m.

Total control

The electronic control device that kick-starts the PaT is powered by a compact Uninterruptible Power Supply (UPS). This contains a smart battery that maintains full charge at all times regardless of how much power is drawn from it and delivers 230 volts at 50 cycles. Should the control device detect that the PaT has stopped, it will instruct the UPS to start it up again when necessary.

There is a second task that the control device provides. Ulrich explains: “If you are running any type of power plant, it is designed to supply exactly that quantity of electricity that is needed. If too much is generated it becomes necessary to open up additional circuits, which will simply burn up power. If it is too low, then it will not be able to support the entire load. The control device, in conjunction with a transformer, balances the power output.”

Should the water supply to the turbine be interrupted, then the PaT is automatically shuts down, so it cannot run dry. On the resumption of the water supply, the electronic control device will automatically turn it back on through the UPS module.

The quality of the electricity generated has to be of the highest international standards in order to support all state of the art electronics, such as computers and mobile phones. Because of this the electricity is filtered. There is also a transformer to ensure that the electricity is generated to the correct level and two frequency converters that are connected to the transformer and the asynchronous generator. The transformer is needed to uncouple the energy production from the customer supply side, and ensure that the voltage and current are 100 per cent in line with sensitive equipment requirements.

“The biggest advantage of the Powerhouse is that it the generator is electronically controlled,” comments Ulrich. “Other PaTs rely on mechanical methods of control and these can be expensive and potentially unreliable, plus they are inflexible when the turbine needs to respond to variations in the static head. By employing two frequency converters it is possible to control the output of the generator to provide only the amount of energy actually needed for the load. As the generator is always run at the Best Efficiency Point, the Powerhouse is fully independent of incoming water flow level, which is not the case with mechanical control systems.”

“Historically KSB AG has supplied over 200 small hydropower systems, so in terms of PaTs this amounts to over 3,000, “ continues Ulrich. “The key to the success of the Powerhouse is its reliability. Our considerable research has identified sub-Saharan Africa, South America and the more remote parts of Eastern Europe as being potential markets for Powerhouse. We have already built pilot unit and it is intended that this will run initially for six months in an appropriate location where there is no reliable mains power. The unit has a power output of 40kW, which is sufficient to supply all the needs of a small village (Fig.4).”

Figure 4 - Operating a centrifugal pump as a turbine involves the liquid flowing from the discharge outlet to the suction inlet.