Researchers in the USA and Korea have developed a hydrogen high pressure annealing (HPA) process for aluminium oxide/hafnium dioxide (Al2O3/HfO2) gate stacks on indium gallium arsenide (InGaAs) quantum wells [Tae-Woo Kim et al, IEEE Electron Device Letters, vol36, p672, 2015]. The aim of the team, from SEMATECH Inc in the USA, the Korea Advanced Nano Fab Center in South Korea, Poongsan Inc in the USA, and Kyungpook National University in South Korea, was to reduce interface and border traps that adversely affect transistor performance and threshold voltage reliability.

Although the work was carried out on planar metal-oxide-semiconductor capacitors (MOSCAPs) and field-effect transistors (MOSFETs), the researchers add: "We also believe that the HPA process developed in this work would be invaluable for non-planar InGaAs MOSFETs, such as tri-gate architecture, in the sense of recovering the sidewall gate-stack damage through the annealing step."

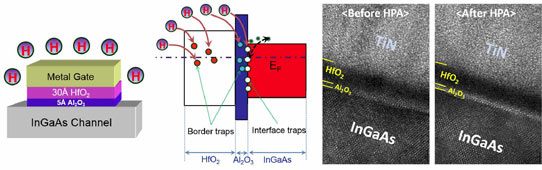

Figure 1: (a) Schematic cross-section for InGaAs MOSCAPs and MOSFETs with HPA, (b) energy-band diagram with interfacial and border traps, and (c) cross-sectional TEM images for Al2O3/HfO2 gate stack before and after HPA.

The researchers see indium-rich InGaAs n-channels as the most promising non-silicon option for continuous scaling down of supply voltages for low-power consumption and boosting transistor performance in future electronics. Although much progress has been made, performance and reliability degradation from interface and border traps continues to be a concern.

The epitaxial material was grown by molecular beam epitaxy (MBE) on indium phosphide (InP). The quantum well channel consisted of 10nm In0.7Ga0.3As on an indium aluminium arsenide (In0.52Al0.48As) barrier layer with inverted silicon δ-doping.

Electrical isolation of the devices was achieved with a wet etch using a solution based on phosphoric acid (H3PO4). Ohmic metals for the source-drain contacts were molybdenum/titanium/gold. The gate region was patterned and Al2O3/HfO2 gate insulators and the titanium nitride gate electrode were applied using atomic layer deposition (ALD).

The last stage was the hydrogen HPA, carried out at 300°C under 20 atmospheres pressure for 30 minutes. The tool used was a Poongsan GENI-SYS system (www.poongsan.co.kr/eng/products/high-pressure-annealing-process-system/).

The researchers say on the basis of capacitance-voltage measurements that the anneal was effective in reducing border traps. Also, the interface trap density (Dit) was reduced by more than 30%, indicating effective passivation (Table 1).

Table 1: Comparison between InGaAs MOSCAPs and MOSFETs before and after HPA.

| Interface trap density | Capacitance equivalent thickness | Subthreshold swing | Drain-induced barrier lowering | On-resistance | |

| Before HPA | 2.0x1012/eV-cm2 | 1.9nm | 130mV/decade | 68mV/V | 540Ω-μm |

| After HPA | 1.1x1012/eV-cm2 | 1.8nm | 105mV/decade | 20mV/V | 520Ω-μm |

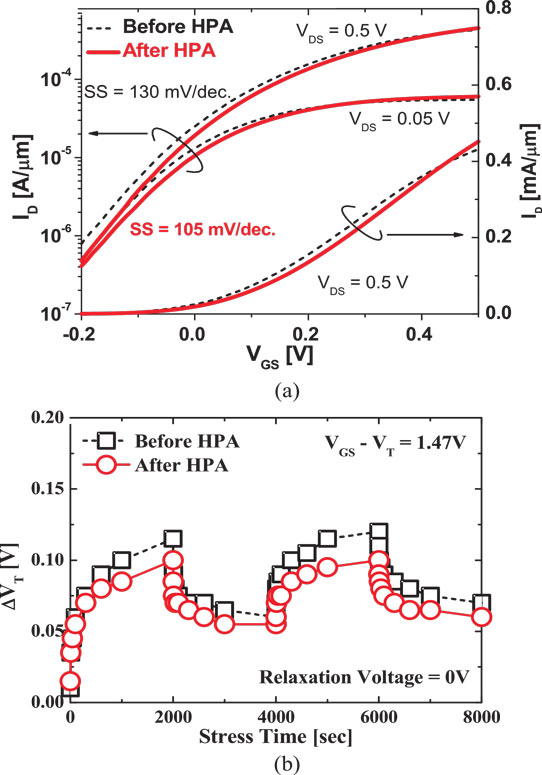

The performance of MOSFETs with 50nm gate length showed reduced subthreshold swing and drain-induced barrier lowering from the anneal process that the researchers describe as "remarkable" (Figure 2a). The researchers comment: "Consistent with findings in the InGaAs MOSCAPs, the improvement in the electrostatic integrity of the InGaAs MOSFETs arises mostly from the reduction of Dit during the HPA process step in this work."

Figure 2: (a) Subthreshold (left) and transfer (right) characteristics of MOSFETs, and (b) ΔVT profile as a function of iteration of constant voltage stress before (dashed line) and after (solid line) HPA.

Constant voltage stress (3.47MV/cm field) reliability tests showed reduced threshold voltage shift (ΔVT) from annealed devices (Figure 2b). This was attributed to the reduction in border traps.