The UK’s University of Cambridge has opened a new £1m facility for growing gallium nitride that aims to enable researchers to expand and accelerate their work, which promises to further reduce the cost and improve the efficiency of LEDs.

The new GaN growth reactor at Cambridge will allow researchers to further improve existing methods for growing low-cost LEDs on silicon substrates, reducing their cost by more than 50% and opening them up for more general use.

LED technology is already so energy-efficient that it is estimated that the overall demand for electricity would fall by at least 10% if every home and business in the UK switched to LED lighting. This could save the UK over £2bn annually in electricity costs, it is reckoned. Further developments planned in the new reactor could result in an extra £1bn in savings.

In addition, researchers are developing color-tunable LED lighting with the quality of natural sunlight, which would bring health benefits to users.

Funded by the UK’s Engineering and Physical Sciences Research Council (EPSRC), the new reactor was opened by David Willetts MP, the Minister for Universities and Science, marking the latest chapter in a decade-long research project on LEDs for lighting applications led by professor Sir Colin Humphreys of the Department of Materials Science and Metallurgy.

In 2003, Humphreys and his team began experimenting with growing GaN on silicon instead of costly sapphire and silicon carbide (SiC). Last year, their process technology was picked up by UK-based manufacturer Plessey, which has since started manufacturing LEDs at its factory in Plymouth. Plessey also hired three of Humphreys’ post-doctoral scientists to help transfer the process.

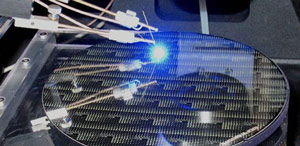

Picture: GaN LEDs grown on a silicon substrate. Credit: University of Cambridge Department of Materials Science & Metallurgy.

“At the moment, a 48-watt LED lightbulb, made from GaN-on-sapphire LEDs, costs about £15,” says Humphreys. “That’s a cost that you make back several times, because the bulbs last for so long, but it is too much to convince most customers to buy them. The research we have already performed on GaN-on-silicon LEDs, plus that which we will carry out in this new reactor, will mean that soon people will be able to buy an LED bulb for just £3 instead,” he reckons.

“LEDs are highly energy efficient but expensive to produce, meaning their domestic use is limited,” commented Willetts. “This excellent new facility will enable researchers to look at more cost-efficient ways to produce LEDs.”

Humphreys is also investigating ‘smart lighting’ systems, in which LED lights coupled to a sensor would be able to switch themselves on and off, or alter their brightness, relative to a user’s presence or levels of natural daylight in a room.

Also, as their use increases, the beams from LEDs could be used to transmit information, for example from traffic lights to cars, it is forecast. “The two could be developed to talk to one another,” Humphreys says. “Traffic reports, such as information about a road accident, could be sent to traffic light systems. They could then relay the details to drivers by transmitting it through the headlamps.”

In addition, since deep ultraviolet (UV) radiation kills bacteria and viruses, UV LEDs can be used to purify water supplies in the developing world. Placing a ring of UV LEDs around a water pipe at the point where it enters a home could kill off bacteria in the water as well as other undesirable organisms, such as mosquito larvae.

Humphreys and his team are also currently investigating the ‘green gap’ problem. With blue LEDs currently used to make white light, the color-changing phosphor coating is not completely energy efficient, so a better way of making white light could be by mixing together blue, red and green LEDs. However, this depends on resolving lower efficiency in green light compared with the other two colours. If this can be addressed, and LEDs made the standard for lighting, then there could be an extra electricity saving of 5%.

Cambridge researchers are also starting to investigate GaN’s potential in electronics. Using GaN instead of silicon can improve energy efficiency in power electronics (devices, circuits and systems that manage electrical energy). Humphreys and colleagues from several other UK universities have just been awarded a grant by the EPSRC to develop and prototype highly efficient GaN power electronic devices that could underpin new applications in sectors such as the automotive, aerospace, consumer electronics, lighting, healthcare and energy industries. “If we can replicate these devices with GaN electronics, we believe that we could make them 40% more efficient,” Humphreys reckons. “That in itself would translate into a 9% electricity saving.”