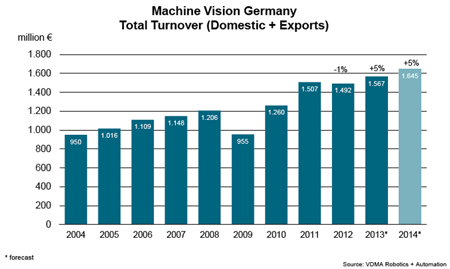

The German machine vision (MV) industry is on a stable growth course. According to the latest market data from the country’s VDMA Machine Vision Association, in 2014 the sector will enjoy growth of five percent to surpass the sector turnover of close to €1.5 billion achieved in 2013.

Due to a healthy order situation the German machine vision industry expects a growth of five percent this year resulting in a total turnover of €1.64 billion. Impetus for demand is expected to come mainly from sales in North America and Asia.

This growth underscores the trend of recent years: Exports from Germany to Asia exceeded the volume of deliveries into all European countries for the first time in 2012. Between 2008 and 2012 German vision system exports to Asia had already more than doubled. In the same time period exports to the Americas had risen by 64%, while business with Europe had been largely stagnant.

On 4 February, the organiser of the two-yearly Vision Show in Stuttgart, jointly hosted a CEO roundtable in Frankfurt with Germany’s VDMA Machine Vision Association. Participants discussed the different levels of importance attached to MV in the global markets.

Senior industry representatives were asked to examine the MV market situation and to assess the further development of these technologies. Views were taken on key issues such as the status of machine vision today, how will it develop in the future, and the role MV is playing in the industrialisation of Europe and industrial renaissance in the USA.

Turnover of German machine vision sales in 2012.

International perspectives

Mark Williamson, of Stemmer Imaging UK, commented: "The MV industry is outstripping growth of traditional industrial markets. This growth is driven by the need for efficiency and we see this increasing as there’s a higher drive for reducing costs. We’ve seen significant cost reductions in machine vision technology which is making it more affordable and that’s driving growth significantly.”

Donato Montanari, of Datalogic Automation, Italy, added: “Consumers are becoming much more conscious about product quality. They want to look and feel high quality when they see new products. So businesses must inspect more and more. This will be driving machine vision growth over the next ten to twenty years.”

Commenting on the situation in the USA, Jeff Burnstein, President of the Automated Imaging Association, said: “We see a tremendous future for MV in manufacturing as part of the re-industrialization of North America. More and more manufacturing is returning from overseas to the US. And that is great for anyone in the automation industry, especially the MV sector.”

Mike Cyros, CCO, Allied Vision Technologies, USA, said: “We see two key areas that are driving this re-industrialization in the USA. The first is what we refer to as re-shoring - the migration of labour and production jobs. The reason it’s coming back is for higher quality manufacturing and that is driving the need for more automation technologies including machine vision. Secondly that’s combined with the strong resurgence of our automotive industry.“

Considering Asia, Sungho Huh, of Envision, and the Korea Machine Vision Industrial Association, said, “As labor cost is increasing in Asia, these territories are less attractive for labor-intensive industries. Many OEM companies want to increase the price-performance ratio and quality control. So they are trying to increase usage of robot systems and vision technologies.”

Hersem Yang, of Azure Photonics, China, agreed that labor cost was a big driver for MV growth: “Machine vision has undergone faster growth in China where the economy is in need of automation. The whole market has become mature and labor costs in China are increasing year by year. Therefore more and more companies are building up automation systems to reduce production costs.”