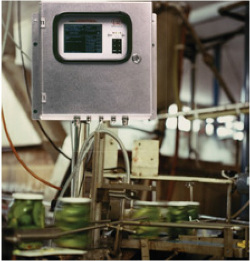

After preserving jars are filled and closed they must be vacuum-tested in fully automatic operation to immediately sort out any defective containers. During transport of the jars an eddy-current sensor scans the lid shape that is generated by the vacuum in a non-contacting way. The subsequent electronic unit calculates lid bending, which directly depends on the internal pressure, with high accuracy. After comparing this value with a specified permissible value range a decision is made about the quality of the internal pressure and thus about the tightness of the preserves container.

Reasons for choosing the system:

- Fully-automatic, non-contacting vacuum test

- Optimum adaptation to the production process

- Almost unlimited service life without system disturbances

- Environmental influences such as moisture, pungent vapours (vinegar) in the field of wet and sticky food, and temperature fluctuations must not influence the function of the system

- Counter for total throughput and for the number of ejected glasses

The Micro-Epsilon Eddy Current sensors from Bestech Australia are water proof with 3m cable and light barrier to detect cans without lid or tilted cans.