Now established in curing, UV LED technology is expected to find growth opportunities in disinfection, purification and other new applications by 2017, says a market analyst. Under its new technology and market report entitled UV LED – Technology, Manufacturing and Application Trends, Yole Développement reviews the traditional UV lamp business and its transitioning to UV LED technology. It says that a notable factor is that industry players have confirmed their interest in cheaper and more compact technology.

Yole’s report presents a comprehensive review of all UV lamp applications including a deep analysis of UV curing, UV purification and disinfection and analytical instruments The analysts also detail the market volume and size metrics for traditional UV lamps and UV LEDs over the period 2008-2019, with splits by application for each technology.

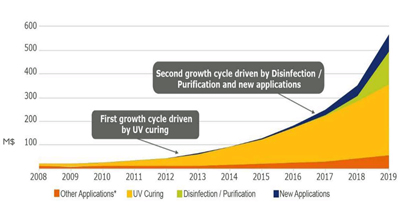

UV LED technology, with its compactness and relative low cost of ownership, continues to make its way in the booming UV curing business, through replacement of incumbent technologies such as mercury lamps. Pars Mukish, Business Unit Manager, LED activities at Yole, commented, “Thanks to this an overall UV LED market that represented around only $20M in 2008, grew to~$90M in 2014, at a compound annual growth rate of 28.5%”.

"Such growth is likely to continue as LED-powered UV curing spreads across ink, adhesive and coating industries. And Pars Mukishe explained, “By 2018, the UV LED market should also see part of its revenues coming from UVC disinfection and purification applications, for which device performance is not yet sufficient. The UV LED business is therefore expected to grow from around $90m, in 2014 to at least $520m in 2019.”

Mukish added, “The potential is even greater, if we consider UV LEDs’ ability to enable new concepts in areas like general lighting, horticultural lighting, biomedical devices, and in fighting hospital-acquired infections”. Even this is just scratching the surface of UV LEDs’ real potential. While the new applications do not yet have a strong impact on market size, Yole expects them to count for nearly 10% of the total UV LED market size by 2019.

In 2008, Yole started its investigation on the UV LEDs technologies. Then, fewer than ten companies were developing and manufacturing these devices. Recently, however, more than 50 companies have entered the sector, over 30 of these between 2012 and 2014, mostly attracted by the high margin when the overcapacity and strong price pressure from the LED TV crisis had taken its toll on the visible LED industry.

Now, some big companies from the visible LED industry – namely Philips Lumileds and LG Innotek – have also secured a foothold in the UV LED business. According to Yole’s analysis, the entry of these two giants will help to further develop the industry, the market and the technology based on their strong experience of turning around the visible LED industry.

Pars Mukish commented, “A good example of this is that thes UV LED sources have made a nearly full transition of their process to 6 inch sapphire substrates. Compared to a 2 inch based process, this can provide at least a 30% overall productivity increase, which would help to further reduce manufacturing cost.”