Jeanine Chrobak-Kando,Business Development Manager for LED lighting at Verbatim,considers how OLEDs are evolving as complementary sources of indoor lighting.

Organic light emitting diodes(OLEDs)now appear in a host of commercial electronics applications,most commonly in displays for radio displays in high-end cars,tablet PCs,mobile phones and other consumer gadgets.But what about OLEDs as general light sources?To understand the potential for OLEDs in lighting,let's start with a little technical background.

How OLEDs work OLEDs work by sandwiching a layer of organic material between two electrodes,an anode and a cathode,and depositing the whole thing onto a substrate,typically glass or plastic.When a low DC voltage is applied to the electrodes,light is emitted as electrically charged particles that combine within the organic film.The characteristics and intensity of light emitted,and how it is extracted from the OLED assembly,determine its suitability for lighting applications.One challenge for OLED development engineers has been how to create large panels.In general,the larger the panel that can be printed in one process,the lower the cost of the OLED light–there's no need to fix a lot of individual panels together to achieve sufficient luminous intensity.Processes and materials limitations determine how large a panel can be made.Another important consideration is the operating life of OLEDs.The higher the light output,the more limited the life of the device,so the most appropriate trade-off for each application has to be made.

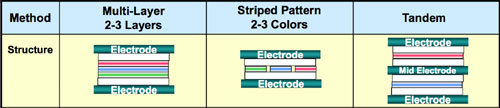

OLEDs can be made in one of 3 ways,as shown in Figure 1.

Figure 1:The striped pattern maximizes light output and makes colour tuning possible Some leading manufacturers favour the multi-layer type on the left,and it's the simplest process.The tandem construction is a little more complex but delivers more intense light output and larger formats can be created.Tandem construction is sometimes combined with the multi-layer structure.The approach taken by Mitsubishi Chemical,which markets OLEDs under the Verbatim brand,is shown in the centre of Figure 1.Narrow stripes of adjacent red,green and blue OLEDs are deposited.This method of production is more complicated but yields two advantages.Each layer within an OLED has a different refractive index.This causes internal reflections within the device that limit out-coupling–the proportion of light generated that reaches the outside environment.The RGB stripe construction is the most effective in maximizing the light output for a given energy consumption.The second advantage is that the OLED is not only dimmable,as with other types of construction,but also colour tunable and white-tone tunable.Dimming does not affect colour.

Manufacturing processes for OLEDs seek to maximize light output and minimize pixel defects.To achieve these aims,in place of the dry process of vapour deposition of the layers that make up the OLED,Mitsubishi Chemical uses a wet process.This avoids defects in the OLED structure when microscopic particles of foreign material are encountered.The liquid simply flows around the offending particles,reducing the roughness of the substrate.

Desirable characteristics for OLED lightingAs mentioned earlier,OLEDs need a large emission surface to be suitable for lighting applications so that they emit sufficient light to be useful.The quality of light,usually expressed as its Colour Rendering Index(CRI)is important in rendering colours accurately.Low power operation,meaning high efficiency in converting electricity to light,is vital in a world focused on reducing energy consumption and CO2 emissions.Also,in common with the requirements of OLED displays,OLED lights should not contain hazardous substances,need to be simple to operate,and must exhibit fast on/off response.

Shining the light onto eight different coloured tiles,numbered R1 to R8,and analyzing the spectrum of the light reflected from the tiles determines the CRI of a light source.Perfect colour rendition equates to a CRI of 100 for each colour.In general CRI is quoted as the average figure across all of the test colours,the CRI Ra figure.Today's OLED panels exhibit a CRI of 84 at R9 and a CRI Ra of greater than 80.

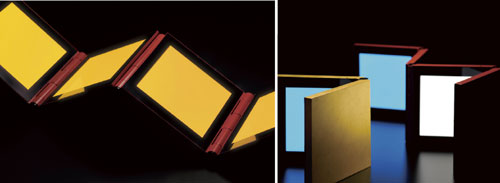

What's available today?The latest dimmable,colour tunable and white tone tunable OLED panels are available in sizes up to about 140mm x 140mm,as shown in Figure 2.

Figure 2:OLED panels up to 140mm square are dimmable,colour tunable and white tone tunable

They offer luminance(light output)of approximately 1000 cd/m2 at a colour temperature of 3000k(within the'warm white'category),enhanced by a light extraction film on the luminous surface.Power consumption is about 2 Watts.Panels are typically between 3.6 and 8.65mm thick and have an operating life of over 8000 hours.Operating life,which equates to over 5 years at 4 hours-per-day before the output has fallen to 70%of its initial value.

The white tone is tunable from 2700K,a typical'warm white'figure,to about 6500K,equivalent to bright sunlight.

Using a simple 3-channel electronic controller located on the back of each panel,the colour can be tuned virtually instantaneously.?Using this feature,together with dimming,the emotional impact of a lighting scheme based on OLED panels can be changed to reflect the mood required for the environment.

The possibilities for creative lighting schemes in domestic and commercial environments are unlimited.Figure 3 shows a Verbatim exhibition display of OLED lighting as a simple example.

Figure 3:A Verbatim display designed in collaboration with Uchihara Creative Lighting Design Inc.(Photography by Toshio Kaneko).

OLEDs are not yet ready to replace general indoor lighting,as has been suggested by some enthusiasts.However,their development has reached the stage where they complement ambient lighting and task lighting,to produce beautifully balanced lighting schemes both in places of work and in the home.Their potential in retail environments and other public spaces is unlimited and their low power requirements meet the demands of the most ardent environmentalists.