Getting a Grip on a Slippery Situation

General Cable is a leader in the development, production, and distribution of aluminum, copper, and fiber-optic wire and cable products for energy, industrial, specialty, and communications applications. Among General Cable's manufacturing facilities, the Altoona, PA plant has distinguished itself as the world's leading producer of OEM and aftermarket ignition wire sets, turning out over 200,000 sets a week.

Assembling ignition wire sets is an oily job. Lubricant from the equipment drips onto the floor, creating slippery working conditions in work cells. So when associates voiced concerns about ergonomics and safety, supervisors teamed up with them to find solutions.

Dealing with a Slippery Situation

"Because we're taking a number of components and trying to get them to slide over the top of a terminal and onto a wire, we need to use lubricant to make the assembly easier," explains cell coordinator/standard team leader Bill Whalen. "Our associates were working on the concrete with all of that lubricant on the floor. They had to be conscious about where and how they were moving every second of the day."

"We installed nonslip tile in the cells but we didn't have anything for the associates to step on when they came out of their work areas," adds Lisa Smith, cell coordinator II/team leader. "They would track lube all over the floor and you could see it getting slippery. That's when we put down the rental rugs."

Rental rugs were a step in the right direction, but they created a new set of problems for associates who needed to move heavy louver carts in and out of their cells.

"They would bunch up under the wheels," says Whalen. "After a week, they'd get so saturated that you'd still slide. We knew we needed to find something different. That's when we got involved with New Pig."

New Pig had been supplying the General Cable Altoona Plant with absorbents such as socks and mats for several years. When account rep Leah Sheffer heard about the problem with the rental rugs, she suggested a new product - PIG Grippy Mat - as an alternative.

Grippy Mat is the only absorbent with a full-coverage adhesive back that keeps it in place while it absorbs oily residue and other liquids.

To find out if PIG Grippy Mat could stand up to constant foot and cart traffic, General Cable tested MAT32100, the standard version, and MAT3223, Grippy Traffic Mat Rug. Both mats absorbed the lube from associates' shoes and stopped it from being tracked around. Both mats stayed in place under the heavy louver cart wheels — but the added durability of Grippy Traffic Mat Rug kept it on the job for weeks at a time, even in extreme conditions. Fewer changeouts lowered costs and improved efficiency without sacrificing employee safety.

"Grippy Traffic Mat Rug doesn't bunch up like the rental rugs and it absorbs a lot better," Whalen relates. "We've had nothing but positive feedback on it."

Reducing Fatigue Increases Productivity

Replacing rental rugs with PIG Grippy Traffic Mat Rug was one piece of the puzzle; finding the right nonslip tile for work cells was another. The tile that had been installed previously provided traction, but it created more problems than it solved.

"I called Leah because we got complaints from our associates about the nonslip tile not lasting very long and being difficult to stand on — hurting their back and legs," recalls EH&S coordinator Steve Clinton. "And the mineral oil overspray on the tile caused the soles of their shoes to wear out quickly. That was a major issue. So we wanted to find a different kind of tile that would meet our ergonomic needs."

With help from Leah Sheffer and New Pig, the team at General Cable set out to discover exactly what was causing the original nonslip tile to break down. New Pig consulted with chemists from several of their tile manufacturers to determine what products were compatible with mineral oil and then provided samples for volunteer associates to test in their work cells.

"We told our associates that we wanted to find what fits the best and lasts the longest in the cells. We took into account the wear on their shoes and how they felt physically after working on it during their shift," says Clinton. "Then once we had the data, we would pick the best tile to use throughout the plant. There was a lot of trial and error, but our associates knew it would take time to get everything right and they were willing to work with us."

Finding the ideal balance of traction, anti-fatigue properties, and absorbency took months of testing, but the associates stayed with it, trying out combination after combination and giving the team important feedback on each one.

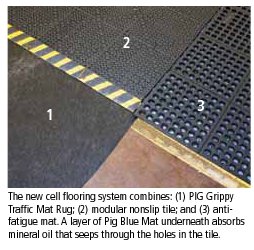

The result of their hard work and persistence was a unique floor system. Cells with louver carts were equipped with FLM311, a modular nonslip tile mat, in the center and FLM810, Niru Cushion-Ease GSII Anti-Fatigue Mat, around the perimeter. Cells without carts used only the FLM810. A layer of BLU102, heavyweight Pig Blue Absorbent Mat, was installed under the entire area to absorb oily drips and overspray, and MAT3223, PIG Grippy Traffic Mat Rug, was placed across the cell entrance to absorb oily residue before it was tracked into walkways. Associates with carts could easily move in and out of their cells and everyone could work comfortably throughout their shift.

"Thanks to these products from New Pig, people can move around more freely and know they're safe," says Whalen. "Because they feel a lot more confident, they can move a lot faster and produce more efficiently."