Fujifilm Corporation and imec have developed a new *photoresist technology for **organic semiconductors that enables the realization of submicron patterns. (For * please see note at bottom for further explanations.)

Due to their lightness, flexibility, and the possibility to manufacture them in large area, R&D on organic semiconductors has intensified in recent years. Organic semiconductors can be used in various applications such as organic solar cells, flexible displays, organic photodetectors and various other types of sensors. Current methods for patterning organic semiconductors include shadow masking*4 and inkjet printing*5. However, these patterning methods are not suitable for high-resolution patterning on large-size substrates. Patterning based on photolithography*6 would solve this issue. But photolithography is currently mainly adopted for patterning of silicon semiconductors. When applying it to organic semiconductors using standard photoresists, the photoresist dissolves the organic semiconductor material during processing.

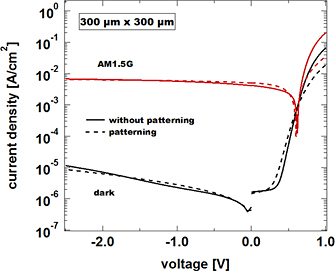

Organic semiconductor materials were patterned to form OPD of 300μm×300μm size, and photoelectric conversion property with irradiation of artificial sunlight (AM1.5G) (red dotted line) was examined. When compared with photoelectric conversion property without patterning organic semiconductor materials (red solid line), it did not show degradation due to patterning.

Similarly, there was no difference between with patterning (black dotted line) and without patterning (black solid line) for unirradiated dark current. (LEDinside/Fujifilm)

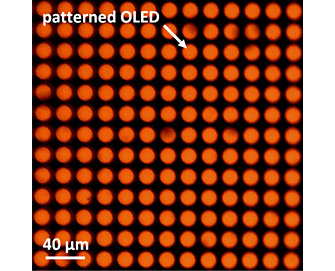

15μm diameter OLED dots were arrayed with 20μm pitch by patterning deposited small molecule organic semiconductor materials with the new photoresist technology. It was confirmed that each dot emitted uniform light.(LEDinside/Fujifilm)

Fujifilm and imec have developed a new photoresist technology that enables submicron patterning on large-size substrates without damaging the organic semiconductor materials. The new photoresist technology was developed by fusing the semiconductor processing technology of Fujifilm and imec, with Fujifilm’s synthetic-organic chemistry material design technology. Since existing i-line photolithography equipment can be used, and investment for new equipment is unnecessary, the new technology contributes to a cost-effective production of high-resolution organic semiconductor devices.

For technical verification, Fujifilm and imec developed organic photo detectors (OPD)*7 and organic light-emitting diodes (OLED)*8 using the new photolithography technology, and tested their performance. Organic semiconductor materials were patterned to produce OPD composed of fine light receiving elements down to 200μm×200μm size. Generally, patterning of organic semiconductor materials degrades the property of converting light into electricity (photoelectric conversion property), but the OPD developed in this case were patterned without degradation. With respect to the OLED arrays that were produced using the newly developed photolithography pattering method: 20μm pitch OLEDs emitting uniform light, were realized.

Fujifilm and imec will continue to contribute to industrialization of organic electronics by advancing research and development of semiconductor materials, processing technology and system integration.processing technology and system integration.

Notes:

* Photoresist: Photosensitive materials that cause photochemical reaction due to light exposures, have different developer solubility at exposed parts and unexposed parts, and are used for microfabrication in semiconductor production. **Organic semiconductor: Small molecule organic compounds and polymers carrying the property of a semiconductor ***Submicron: 1/10000mm. 1/10 micron. *4 Shadow masking method: Patterning by evaporating materials from above the shadow mask (shielding mask) patterned with holes *5 Inkjet printing method: Patterning by injecting material particles from the inkjet nozzle. *6 Photolithography method: A film is formed by coating photoresist onto the substrate to be processed, and photochemical reaction occurs within the resist film by exposing patterns through the mask. This microfabrication method forms a mask-like resist pattern on the substrate through development, and transfers the resist pattern onto the substrate as protective material for etching. *7 Organic photo detector: Photodetection element using organic semiconductors *8 Organic light-emitting diode: Light-emitting elements using organic semiconductors