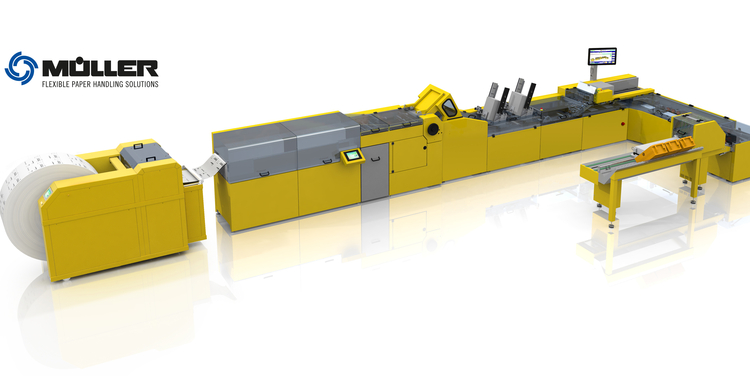

Müller and Kern Investment Consulting Management (KICM) have launched a new multi-format, high-performance inserter system.

Available from this fall, the new inserter system will be exclusively produced and distributed by Müller in global markets.

Müller said that the system will meet the requirements of output centers and services bureau based on the design concept and the high productivity.

Capable of handling up to 28,000 insertions per hour at formats up to B5 and up to 14,000 insertions at B4 envelopes, the system is manufactured at the main plant of Müller near Munich in Germany.

An exclusive long-term technology partnership deal has been signed between Müller and Kern-ICM in order to meet time-to-market requirements and to offer the most advanced product.

Müller sales and marketing director Max Andelshauser said: "The new inserting system is another important product along with the high-performance cutting line in our growing portfolio in the 150-meter class (500ft class).

The innovative concept of the new system perfectly reflects our slogan: flexible, intelligent, efficient. With the new lines we will be able to serve two different concepts: Customized modular solutions for the mid volume market and multi-format-solutions for the high volume market."

The system is also designed to have a maximal insert thickness of 13mm and process many paper and envelope formats without compromising productivity.

The firms are planning to display their new cutting and the inserting system in the 150-meter class at Drupa printing equipment exhibition scheduled to be held in Germany.

Image: Illustration of multi-format, high-performance inserter system. Photo: courtesy of Müller.