Toshiba Corporation announced that the company will start sales of white light-emitting diode (LED) packages that offer makers of general purpose and industrial LED lighting solutions a cost-competitive alternative to current LED packages. Mass production will start this month.

Production of LED chips is typically done on 2- to 4-inch wafers with an expensive sapphire substrate. Toshiba and Bridgelux, Inc. have developed a process for manufacturing gallium nitride LEDs on 200mm silicon wafers, which Toshiba has brought to a new production line at Kaga Toshiba Electronics Corporation, a discrete products manufacturing facility in northern Japan. Mass production of packages using the new line's output starts this month.

Deployment of Toshiba and Bridgelux's new gallium nitride-on-silicon (GaN-on-Si) technology to produce LED chips has allowed Toshiba to replace sapphire substrates and to produce the chips on a much more cost-competitive silicon substrate.

The low power consumption and long life of the white LED lighting is winning wide adoption in general purpose lighting, TV backlighting and other areas of application. In FY2011 the global market stood at 700 billion yen (approximately US$8.5 billion) and it is expected to almost double to 1,250 billion yen ($15.2 billion) in FY2016.

Going forward, Toshiba will promote product development and global sales toward securing a 10% share of the world market in FY2016.

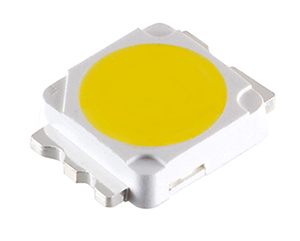

Product Outline

| Product name: | TL1F1 series (1W) |

| Size: | 6.4 mm (L) x 5.0 mm (W) x 1.35 mm (H) |

| Light flux: | 112 lm (at 350mA) |

| Mass Production start: | December 2012 |

| Production capability (planned): | 10,000,000 units per month |