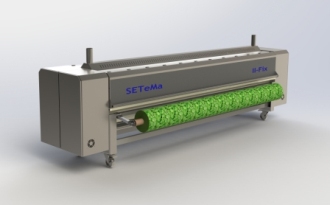

Five years after introducing I-Fix, Netherlands based Setema, a producer of fabric finishing equipment, mainly for printing will show a complete newly developed high speed II-Fix, for the fixation of disperse dyes and pigments up to 5 metres width at FESPA 2015 at hall 7, stand N-8.

In a press release, it said, looking at customer’s requirements Setema has seen a growing market demand for faster and wider dry-heat fixation equipment consistent with the increasing speed and width of the digital disperse printers and an upcoming interest in pigment as well.

Nop Elemans director of Setema and developer of the II-Fix said, “Customers not only require a higher fixation speed for disperse dyes, but also for the pigment printing segment. Our experience of the last five years with our first I-Fix range has been put into the II-Fix.”

The result is a compact and efficient fixation unit suited for both, disperse and pigment fixation. The new developed II-Fix achieves a four times higher output compared to the existing I-Fix and to make the II-Fix fit for pigment, Setema increased the capacity since pigment requires a much longer contact time than disperse.

The II-Fix is a complete autonomous heat fixation unit that can be used as a stand-alone fixation unit to keep up with several printers or, as like the I-Fix, it can also be coupled in-line to any digital printer without the need of a mechanical or electrical interface and textile printing and heat fixation are automatically synchronised to a one step process.

Advantages of the II-Fix include, maintaining the textile structure due to the pressure-free heat fixation, supporting in-line workflow as well as stand-alone process, small operating space, operational within 15 minutes, low overall energy consumption due to closed isolated chamber and an integrated exhaust removes hazardous solvents, which evaporate easily at high fixation temperatures from the ink, thereby keeping the working environment clean.

Other benefits are that even if placed behind the printer, the II-Fix will not influence the printing process with heat generation and evaporated solvents, offers high functionality and productivity at a low price, is also suitable for universal drying applications and is available in fabric widths of 1.85, 2.50, 3.40 and 5.00 metres.

With temperatures between 50 and 220°C and contact times from 15 seconds till several minutes the II-Fix is suitable for a wide range of fixation and drying applications. The electrical heated aluminum drums provide an even temperature in the full width and guarantee a quick heat transfer to the textile.

The cleaning is also easy because the exhaust hood can be opened; allowing access to the drums and the II-Fix is delivered complete with its own embedded control-unit.

Based in the Netherlands, Setema B.V., which was founded in 2002, develops and manufactures machinery for dyestuff fixation, coating/padding, washing, finishing and drying of textiles and is focused towards all textile finishing processes around printing. (AR)