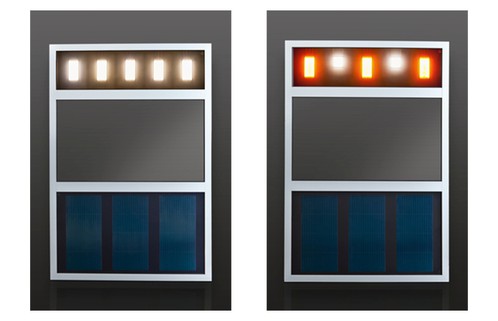

The manufacturing of individually designed organic light-emitting diodes and solar cells and their combination can be realized in the near future. After three years the project ManuCloud (distributed Cloud product specification and supply chain manufacturing execution infrastructure), which was funded by the European Union, now successfully completed its work. As result the project partners Heliatek, Fraunhofer COMEDD, Tridonic Dresden and GSS Gebäude-Solarsysteme GmbH presented a demonstrator of a façade module, which combines the OLED- and OPV-technology. The objective of the ManuCloud project was the development of a service-oriented IT environment as basis for the next level of manufacturing networks by enabling production-related inter-enterprise integration down to shop floor level. Industrial relevance was guaranteed by involving industrial partners from the organic photovoltaic, organic lighting and automotive supply industries.

The transition from mass production to personalized, customer-oriented and eco-efficient manufacturing is considered to be a promising approach to improve and secure the competitiveness of the European manufacturing industries in the future, which constitute an important pillar of the European prosperity. One precondition for this transition is the availability of agile IT systems supporting this level of flexibility on the production network layer on the one hand and on the factory and process levels on the other hand.

The European Union´s Seventh Framework Programme funded project ManuCloud was setup in 2010 with the mission to investigate the production IT-related aspects for this transition and to develop and evaluate a suitable IT infrastructure to provide better support for on-demand manufacturing scenarios, taking multiple tiers of the value chain into account. On this path, the ManuCloud members implemented the vision of a cloud-like architecture concept, providing users with the ability to utilize the manufacturing capabilities of configurable, virtualized production networks, based on cloud-enabled, federated factories, supported by a set of software-as-a-service applications.

Two seminal technologies have been selected to demonstrate the application context for the ManuCloud concept: The organic photovoltaic (OPV) and the organic LED (OLED) technology. Each of them is driven by specific market needs. Both markets are currently in an early stage. However, market research predicts a multibillion dollar market for these products already in a few years. Due to the unique properties of large-area light generation and energy harvesting, coming with special features like adjustable colors, transparency and a thin and lightweight structure, OLAE(organic and large area electronic) technologies are expected to generate numerous new applications with a substantial share being customized solutions. The project has setup and evaluated a manufacturing cloud infrastructure for customized organic lighting and solar cell solutions.

Tridonic Dresden defined application scenarios together with the partners based on discussions with potential customers of the manufacturing environment. The demonstrated façade element was identified as one interesting scenario. The definition of the façade element and the setup of the lamination process including setup and test runs were driven by Tridonic Dresden together with Fraunhofer COMEDD, Heliatek and GSS Gebäude-Solarsysteme.The partners developed a process to integrate temperature and pressure sensitive OLED and OPV devices into glass to create an integrated active glass laminate.

The ManuCloud consortium: The ManuCloud consortium was composed of eight partners from four different EU member states (Austria, Germany, Hungary, United Kingdom). The partners were the following: advanced clean production Information Technology GmbH (acp-IT), Robert Bosch GmbH, Fraunhofer Institute for Manufacturing Engineering and Automation (IPA, consortium leader), Fraunhofer Research Institution for Organics, Materials and Electronic Devices COMEDD, HELIATEK GmbH, Tridonic Dresden (formerly LEDON OLED Lighting GmbH & Co. KG), nxtControl GmbH, Computer and Automation Research Institute of the Hungarian Academy of Sciences, and the University of Strathclyde.The research leading to this results has received funding from the European Union´s Seventh Framework Programme under grand agreement number 260142.

About Tridonic Dresden:

Since July 2013 Tridonic Dresden GmbH & Co. KG is a 100% subsidiary of the Zumtobel Group. Originally Tridonic Dresden was founded as a joint-venture company under the leading of LEDON OLED Lighting GmbH & Co. KG by the Zumtobel Group together with the Fraunhofer Gesellschaft and some employees of the Fraunhofer Institute for Photonic Microsystems (IPMS) in autumn 2009. The head office is in Dresden – one of the most important centers for OLED technology in Europe.

Main aim of Tridonic Dresden is the further processing and finishing of OLED lighting elements to applicable OLED modules. Some of the core competencies are the electrical integration and electronically control and driving of OLED lighting modules as well as the improvement of the quality of light.