Bosch Packaging Technology will display two new pharmaceutical inspection machines capable of conducting container closure integrity and high-end leak tests, during Achema 2015 to be held in Germany from June 15 to 19.

While the KHS 1 is designed for testing container closure integrity for ampoules, vials, bottles, cartridges and syringes using laser headspace analysis (HSA), the AIM 3 performs both visual inspection and high-voltage leak detection (HVLD) on a single platform.

Bosch Inspection Technology business development manager Mahmoud Hamada said: These new platforms underline the expertise of Bosch Packaging Technology in all inspection areas.

"Our aim was to offer pharmaceutical producers and contract manufacturers from all over the world an economical solution for medium speeds at high Bosch quality standards."

Designed in collaboration with Lighthouse Instruments, the KHS 1 detects leaks by measuring the light absorbed while passing through the headspace region.

Using laser spectroscopy, it is capable of inspecting both standing and non-standing containers at a rate of up to 600 per minute. It combines HSA with optional near infrared (NIR) measurement and container coding.

Besides, a built-in automatic re-calibration can be constantly carried out using certified reference containers.

The AIM 3 detects leaks by assessing the electrical resistance of containers with conductive solutions. It inspects ampoules and vials containing solutions and suspensions at 400 containers per minute.

Furthermore, its pre-inspection station can mark the damaged container and prevent them from entering the main inspection turret. This has been made possible by a high-resolution CMOS camera with high-speed interface for particle and cosmetic inspection in its core module.

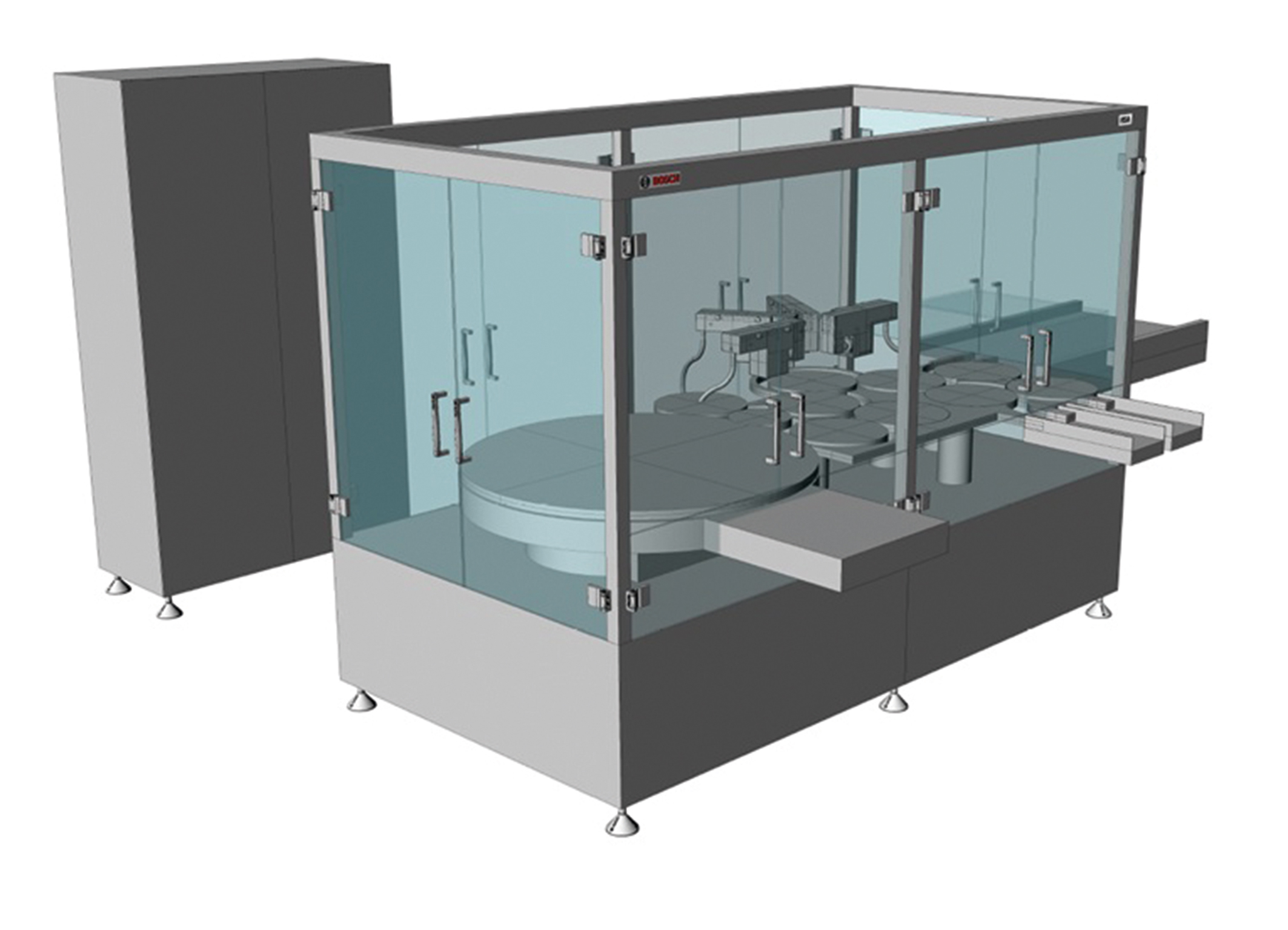

Image: The new KHS 1 is designed for container closure integrity test at 600 per minute. Photo: coutesy of Bosch.