Recently, Mr. Zhongyu Shi was driving a brand new Volvo Trucks FM460, one of the vehicles in the Anhui Liu An Logistics fleet, down the Outer Ring of Qipu Road in Shanghai at nearly 100 km/hour, with a total weight of 55 tons of the truck and the cargo, when suddenly the front left wheel blew out. Thankfully, because new Volvo Trucks vehicles are equipped with Volvo Truck's Dynamic Steering System (VDS), the vehicle maintained its balanced and didn't flip on its side, or even drastically change course, thereby avoiding a massive deadly traffic accident.

Zhongyu Shi, the driver who experienced this unnerving event, has been driving for a decade. When he recalls the situation his heart still has palpitations, and Mr. Shi realizes how incredible it is that he came out of this type of accident unscathed. He explained, “I was driving down the Outer Ring of Qipu Road in Shanghai when I heard a loud noise, the cab of the truck leaned a bit to the left and I knew that the cab's front left steering tire had blown. At the time the truck was moving very fast and pulling a large load of 55 tons, therefore my first reaction was to pump the brake, hoping that the vehicle wouldn’t veer drastically off-course or even possibly roll over. If I had crashed into the guardrail, or swerved into the left lane or even rolled over, consequences would have been unthinkable.”

With a huge sigh of relief, Mr. Shi noted, “But what I hadn't expected was that my steering wheel only made slight movements, and it moved to the left very slowly, and it was almost as if the steering wheel had stayed locked in place. I was able to maintain control. I was so fortunate to be driving a brand new Volvo Truck equipped with the technologically advanced VDS system when this accident occurred. It was due to this equipment that I was able to avoid an accident; if it had been any other vehicle, at this high speed with this heavy loads, the human and economic losses with be unimaginable.” According to the 2013 Shanghai traffic accident compensation standards and vehicle value, this type of accident would cost a logistics company 1.5-2 million RMB in direct losses, as well as 350 hours’ worth of indirect losses, the severe injury or deaths of two drivers, and damages caused to other vehicles on the road and the road itself.

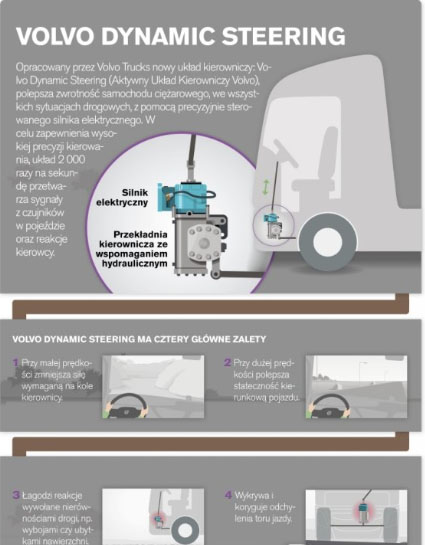

Without question, the name Volvo Trucks is synonymous with ‘safety’. When Volvo was established in 1928 its founders made it clear that safety was a fundamental principle that must be included in all vehicle design. From that time continuing on into the present day, Volvo has been on the leading edge of safety design, holding numerous patented safety inventions. Along with the launch of their all new series of ranges, Volvo Trucks decided to make their innovative, industry-leading patented technology VDS part of each vehicles standard configuration, bringing drivers and logistics companies extraordinary handling stability and security. In Volvo's system an electronically controlled electric motor is added, which is attached to the steering shaft. This electric motor works together with the hydraulic power steering and is adjusted two thousand times per second by the electronic control unit. The VDS system automatically regulates the steering and compensates for irregularities that feed through to the steering wheel, caused for instance by side winds or bumps in the road surface. It can even help reduce the risk of vehicle rollover if a tire blows. This technology is one of the main reasons that Volvo Trucks’ new range has been in high demand ever since they became available on the market. Numerous long-haul logistics companies are very impressed by the huge risk-aversion value that the VDS technology brings them. Safety is always the most solid foundation for efficient transportation operations.

Currently, Volvo Trucks vehicles are favored in the hazardous chemical substances transportation industry and are being used by a number of large international companies such as Messer, Praxair and AP. Volvo Trucks’ new vehicles possess a range of safety technologies, including: Front Underrun Protection System (FUPS), Driver Alert Support (DAS), radar-based Adaptive Cruise Control (ACC), Collision Warning Alerts, expanded range of view and more. These technologies are all necessary to safely transport hazardous chemical substances. Drivers operating Volvo Trucks vehicles generally give them a high rating, saying for example that the cab design is not only comfortable, but that the windshield, rearview mirrors and airbags all effectively protect driver’s safety. The VDS equipped by all new range of Volvo Trucks raises the road safety standards, and reduces the risk of vehicle rollover if a tire blows by automatically regulating the steering and compensates for irregularities that feed through to the steering wheel.

In today’s world, along with the rapid development of the logistics industry, there are greater requirements for a vehicle’s uptime and safety. Volvo Trucks has always adhered to the core concepts of "quality, safety and environmental care", relying on their leading technology, excellent quality products and their perfected service system to bring logistics companies increased value including productivity, fuel-efficiency, uptime, safety, security and driver appeal. Most importantly, Volvo Trucks has been concentrating on safety, and spares no efforts on creating a safe transportation industry.