Every LED maker wants to know the emission wavelength of its final device during metal-organic chemical vapour deposition (MOCVD) growth, says LayTec AG of Berlin, Germany (which makes in-situ metrology systems for thin-film processes, focusing on compound semiconductor and photovoltaic applications).

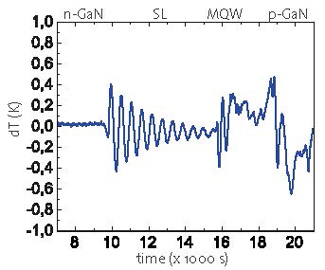

Figure 1: Effect of changing emissivity to UV pyrometer temperature reading: up to 0.7K, errors show up without emissivity correction during growth of a GaN/AlGaN-GaN-SL/InGaNMQW/GaN structure.

Currently, according to the solid-state lighting (SSL) road map, the wavelength variation across a wafer should be less than 1nm. This equals a < 1K variation in gallium nitride (GaN) surface temperature during indium gallium nitride (InGaN) multi-quantum well (MQW) growth. LayTec says that its Pyro 400 pyrometry tool is therefore being widely used to enable fab-wide GaN surface temperature uniformity in the production lines of leading LED makers.

Meanwhile, more complex LED structures and tighter cost-reduction targets are demanding even more advanced in-situ metrology. Figure 1 shows such an example: ternary InGaN and AlGaN layers cause changes in emissivity that lead to a 0.7K error in the UV pyrometry reading.

LayTec's answer to this challenge is the Pyro 400 Gen 2. Alongside in-situ UV pyrometry, this new-generation tool includes real-time UV emissivity correction for enhanced accuracy in GaN surface temperature measurement during the growth of more complex LED structures.

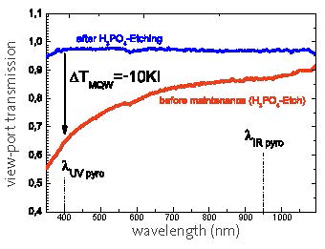

Figure 2: GaN MOCVD viewport before (red) and after maintenance (blue): transmission at the 400nm detection wavelength of a UV pyrometer is suffering from the window coating (red). The resulting -10K artefact is avoided by Pyro 400 Gen2. (Data courtesy of FBH, Berlin.)

A further challenge to reliable GaN temperature control in high-brightness (HB)-LED production is the viewport coating. Figure 2 shows its effect just before maintenance: the UV transmission of the viewport is significantly reduced and an uncorrected UV pyrometer would give a -10K temperature artifact. LayTec says that the Pyro 400 Gen 2 can solve this problem by automatically sensing and correcting these coatings, enabling a long-lasting 24/7 accuracy in HB-LED emission wavelength, it is claimed.

Finally, an assisting infrared (IR) pyrometer has been integ rated into the Pyro 400 Gen 2 for simultaneous monitoring of wafer pocket temperature throughout the full LED growth run.