Plansee uses the creep-resistant tungsten material WVM to manufacture heaters for sapphire growth. These have more than twice the service life of conventional tungsten heaters.

Sapphire growth takes place at high temperatures of approximately 2100 °C. In the Kyropoulos process, rod heaters made from pure tungsten are generally used. These often have to be replaced after just a few cycles. This is due to the high level of embrittlement and deformation. It can sometimes be so extreme that the heater rods touch the shielding and cause short-circuits.

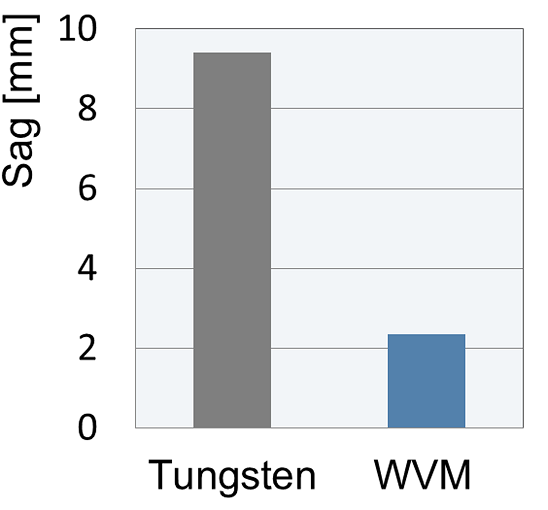

To meet the needs of single crystal growth applications, Plansee has further developed a material that has already earned the plaudits of the lighting industry for its behavior at high temperatures. WVM: The material consists of pure tungsten with very low quantities (30-70 ppm) of potassium. The creep resistance of this material is several times better than that of pure tungsten. This capability was recently confirmed by a sag test performed by Plansee's materials engineers.

Putting WVM to the test

They simulated the use of our material at high temperatures and under various mechanical loads. The sag test proves it: WVM sags four times less than pure tungsten. The reason: The potassium leads to a more stable and coarser crystalline structure than pure tungsten. This property also has a positive influence on the material's creep resistance.

Testing conditions: Temperature: 2100 °C, duration: 6 hours, bending stress: 22 MPa

Rod heaters, mesh heaters, and sheet heaters made from WVM provide excellent dimensional stability, in particular when it comes to high-temperature processes such as sapphire growth. While conventional tungsten heaters have to be replaced after just a few cycles, WVM heaters easily last for 2 to 3 times as long.

At 99.97%, the purity of WVM is the same as that of pure Plansee tungsten. The potassium content in WVM is firmly bound in the material. As a result, it will not contaminate the furnace atmosphere. The material is suitable for use in extremely sensitive high-vacuum processes in the same way as pure tungsten.

Rod type heater for sapphire growth

More products for sapphire growth

But when it comes to sapphire growth, Plansee is able to offer more than hot zones with particularly durable heaters. The company also produces the corresponding pressed-sintered tungsten crucibles. These high purity crucibles have an ultra-smooth surface. The sapphire can be extracted without difficulty from the crucible without any damage to the crucible surface. And the smooth surface is less susceptible to corrosion in contact with the sapphire melt. With their high and homogenous density of over 93 % the crucibles are non-deformable even at high and rapidly changing temperatures.

PLANSEE High Performance Materials.

The Plansee Group is a leading enterprise in the field of powder metallurgy and covers the entire production process from the ore right through to the customer-specific component.

The Plansee High Performance Materials division is an expert in the field of molybdenum, tungsten, tantalum, niobium and chromium components. Whether in electronic applications, medical technology or high-temperature furnaces: When conventional metals come up against their limits, Plansee's alloys and composites take over.