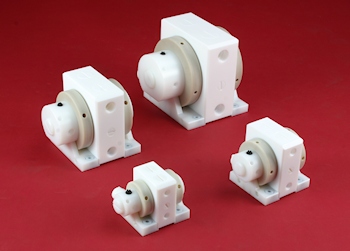

Almatec has designed its Futur Series Pneumatic Diaphragm Pumps for use in specific chemical supply and circulation applications in the semiconductor industry. Realizing the importance of reliable and contamination-free pump performance in critical semiconductor operations, all pumps are cleaned several times, then assembled and tested in a Class 100 clean-room line before being released for delivery.

Almatec is currently offering its Futur Series pumps in five models, all of which incorporate the maintenance-free Perswing P Air Control System, which optimizes air consumption and production rates:Futur T: Designed for delivering acids and caustics, features a wetted center housing of PTFE-TFM and non-wetted side housings of polyethylene. Available in 10, 20, 50 and 100 L/min (2.6-26 gpm) sizes.

Futur H: For hot applications with acids and caustics, this model has a center housing of PTFE-TFM and side housings of PTFE conductive. Available in 10 and 20 L/min (2.6 to 5.3 gpm) sizes.

Futur E: Used for pumping abrasive slurries, this model has center and side housings of polyethylene. Available in 20, 50, 100 and 200 L/min (5.3 to 53 gpm) sizes.

SLS: Used to pump solvents and strippers, this model has center and side housings constructed of 316L stainless steel. Available in 20 and 50 L/min (5.3 to 13 gpm) sizes.

Futur-Omega: The latest member of the Futur family, this model is entirely constructed of PTFE, with the option of polyethylene or 316L stainless-steel construction. Available in 20, 50 and 100 L/min (5.3 to 26 gpm) sizes. The Futur-Omega Series was named an Innovation Award winner by Flow Control magazine as one of the year?s most compelling fluid-handling technologies.All pumps offer diaphragms constructed of PTFE or polyethylene and cylinder valves that seal a large area while permitting accurate product delivery. All of the pumps have a compact, simple design with few parts, with all housing parts machined from solid blocks for long-life performance.