The impact of using a vertical current injection structure was also seen in a higher external quantum effi- ciency (EQE) of 16.2% at 350mA, com- pared with 13.2% for the LLED. At 550mA, the VLED EQE fell 11.9%, com- pared with14.6% for the LLED. Increasing the heat-sink temperature above 298K (~room temper- ature) decreases overall efficiency in these devices, but the degrada- tion is slower for the VLED, com- pared with the LLED. For the temperature range 288–338K, the VLED maintained a roughly constant value with degradation only appearing beyond this. At 378K, the EQE for the VLED was 15.5% (–4.3%) for the VLED at 350mA injection. A further effect of temperature increase is to narrow the energy gap, red-shifting the radiation to longer wavelengths. Between 298K and 378K, the peak wave- length of the LLED shifted from 449.3nm to 453.7nm (0.55nm/K), and the VLED from 449.5nm to 453.2nm (0.48nm/K). By contrast, there was a blue-shift in wavelengths as the current increased to 300mA, after which the wavelength remained constant in the VLED.

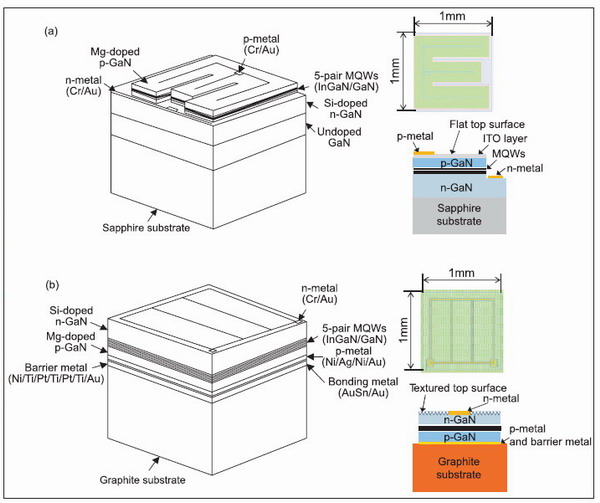

Figure 1. Schematic diagrams of fabricated GaN-based (a) LLED on sapphire substrate and

(b) VLED on graphite substrate with mesa size of 1mm x 1mm.

For the LLED, Joule heating in the devices due to the poor thermal conductivity of the sapphire substrateleads to red-shifting at currents beyond 300mA, because the real junction temperature is higher than that of the thermal stage that was used to control the temperature. The initial blue-shift is ascribed to the quantum-confined Stark effect (QCSE), where the changing electric fieldin the MQWs for different injection currents shifts the energy bands differently and hence affects the emission wavelength. The polarization fields that arise in nitride semiconductors due to spontaneous and piezoelectric (strain-dependent) effects tend to increase QCSEs.

The junction temperatures of the various devices at different injection currents in continuous wave (CW) operation were estimated through the initial forward and the voltage after 30 minutes, when the device had reached thermal equilibrium. The dependence of the forward voltage on temperature was estimated from pulsed measurements at controlled temperatures where thermal equilibrium of the junction is not reached.

In a 298K environment, the junction of the LLED reached 300.6K at 60mA and 312.4K at 350mA (40.74K/A increase). The same experiment on the VLED gave 299.7K and 310.2K (35.68K/A), respectively. The results suggest a thermal resistance of 10.12K/W for the VLED, compared with 12.53K/W for the LLED. Previous work by Kyung Hee University and Korea Advanced Nano Fab Center achieved ~8K/W for a VLED on 100μm copper. Three of the researchers from the new work were involved in this earlier result.

The researchers conclude that "the graphite substrate can be considered as a promising candidate for high- brightness LEDs by the wafer bonding process."