One of the more innovative imaging products on show at last weekend's Digital Show in Melbourne was a 3D printer showcased by Fujifilm.

The technology demonstrated how a tangible item made of thermo-plastic could be produced from a digital file.

Fujifilm said it is looking to make 3D printing technology available to retailers in the near future, providing a business opportunity that would allow them to customise products such as jewellery, toys and interior design products for consumers.

"Fujifilm is also looking to make 3D printers available for consumer purchase from retailers in the near future, enabling the family and do-it-yourself enthusiasts to produce low cost, high quality finished parts for their projects at home," said Fujifilm key account manager – commercial division, Michael Mostyn.

"Although 3D printing has been around since the 1980s, the technology has only recently emerged from speciality prototyping markets," Mostyn said. "However, consumer printers would not have the capacity to produce all of the customised 3D products that would be available in-store through kiosks or online."

The principle of 3D printing is similar to ink-jet printing which uses inks applied as droplets onto paper in thin layers in two dimensions.

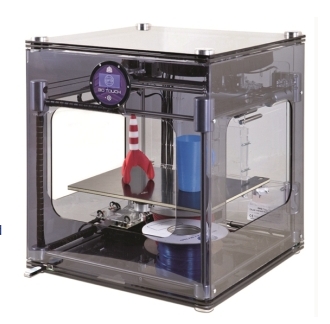

The 3D printer displayed at The Digital Show deposits plastic layer-by-layer to form the object. Various plastics are used in place of different colour inks to produce the desired object.

"In a retail environment, a customer could use a kiosk to create their customised 3D product from a range of customisable designs or even a photograph, place their order with the retailer and then return to the store at a later time to pick up the product," Mostyn said.