China was not like I expected; it was a place rich in culture, beautiful scenes and a heritage that went back thousands of years. The factories we visited were well-established, most were first, second or third-generation businesses. The older generation of factory owners were already starting to delegate more of the day-to-day operations and business to their children, many of whom attended universities in the USA and had college degrees.

In general, factories understood the importance of making quality products and the downside of delivering bad quality. They understood what worked in the past to build good business for both the buyer and the factory, and what resulted in failed business growth.

I have found two primary reasons limiting business growth. First is when price becomes the single driver in placing an order. Often times negotiations with the factory start with, "I want this exact widget, and I need your cheapest price." Once the order quantities and delivery dates are established the price is offered. In most cases, the first reaction is "I need a cheaper price." But when buying and production decisions are based solely on price, results are always the same, you get what you pay for. Experienced factories know how to meet cheaper pricing; it can be backed into by reducing product quality or value.

I've found the best sourcing practice is to begin the conversation with the product first. How can we develop a quality product that an American consumer will buy, be satisfied with, and come back to buy more. Most factories know what they are doing and how to be successful, or they would no longer be in business. Unless a specific type of widget is needed, the factory can offer suggestions on variations to make it a better-selling product.

They may be able to offer alternative colors, materials, shapes and sizes, all with different pricing options. They can engineer to save costs. Only after the final, most sellable product is determined should pricing negotiations begin. Arriving at a final price should be a compromise between the buyer and the factory. More important, it should be a win-win for both parties.

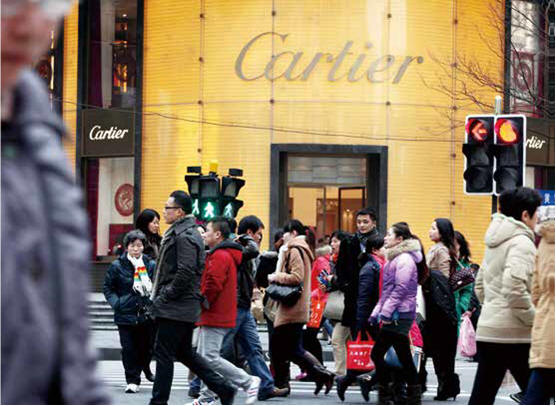

Cultural understanding and building personal relationships are keys. Any business partnership is more successful when both parties understand and value each other as a person. We all enjoy talking about our country and family. While our US history can go back a dozen generations, Chinese history goes back hundreds of generations. Embrace the opportunity to learn about both Chinese culture and the person you're dealing with.

The majority of conversations with a Chinese business partner will be through a translator. The best practice is to make direct eye contact with whomever you are having the conversation with, use slow, simple English with no slang, and pause often for translations. It's also important to be a good listener. While most of the younger generations can speak English, the specifics of a business deal can be lost in translation. Take time to repeat the details, and then repeat them again. Most importantly, make negotiations a positive and personal experience for both parties.

I appreciate the values of hard work, love of family and dedication to successful business within Chinese culture, and have been blessed with the opportunity to establish lifetime friendships in China. While there are differences in cultures, there are very few differences in our heart and soul. My perception of Chinese culture has changed since my childhood, very much for the better. I have appreciated each trip as a great life-learning experience and value the time spent there. My only regret was to find out there were no fire-breathing dragons, but that is probably a good thing.