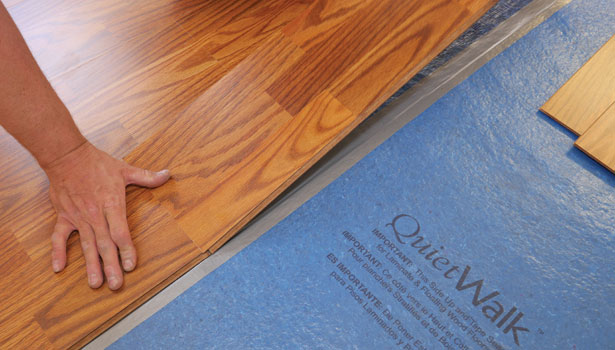

Often considered a throw-in, an afterthought, underlayment for new hard surface glue-down, nail-down and floating floors in residential and commercial installations is anything but. Underlayment that is well matched to the floor covering contributes benefits during installation and for the life of the floor.

The following are six reasons why specialty retailers and contractors should use premium underlayment under new wood—engineered and solid—laminate, luxury vinyl tile (LVT) and ceramic or porcelain tile:

1. During installation, a proper underlayment can help compensate for an uneven subfloor, smoothing out little imperfections and enabling the finished flooring to lie flat.

Premium underlayment is generally denser and has greater compression resistance than entry level products. The underlayment, while firm enough to support the floor, should also be flexible enough to form around the subfloor surface roughness.

2. Improved acoustics. Premium underlayment can provide strong sound deadening qualities that help prevent noise from impacting the room below and help quiet sound in the room in which it is installed.

Look for IIC (Impact Insulation Class) and STC (Sound Transmission Class) sound ratings that meet or exceed your local code. The higher the numbers the better they are at improving acoustics.

IIC tests the ability of a particular floor/ceiling assembly to block impact sound by measuring the resistance to the transmission of impact noise or structure-borne noise. The typical range for an IIC rating is between 20 and 80, with the International Building Code minimum standard for multi-family dwellings at 50 for new construction tested in a controlled lab environment, and at least 45 when tested in an actual building after the floor installation is completed.

The STC test rates the ability of a specific construction assembly (i.e., a floor) to reduce airborne sounds such as from TVs, voices and stereo systems. A rating above 50 would be good. If it’s above 60, it’s that much better.

Manufacturers that test their products and get good results typically post them on company literature, on the company website, and/or on the packaging, making it easy for both the salesperson and buyer to see them.

3. Protection against moisture. Quality underlayment should incorporate a vapor barrier and provide protection against moisture. There are underlayments now available that incorporate a vapor barrier in conjunction with absorbent padding, enabling the wicking away of incidental moisture from a damp concrete subfloor and the disbursing of that moisture through evaporation at the perimeter of the underlayment. Built-in moisture protection helps protect the overlying floor covering.

Floating laminate or engineered wood floors are especially susceptible to damage from moisture coming up from below, such as from a concrete slab on grade. If installed properly, vapor barriers situated on the top side of the underlayment (over the padding) can also help remedy moisture from incidental spills that might flow to the perimeter of a room at the floor’s edge. Although the pad may wick in the spill, the attached vapor barrier keeps the harmful moisture from reaching the bottom surface of the overlying floor, protecting it from potential warping or buckling.

4. Add thermal insulation. Some premium padding provides a measure of insulation and adds an R-value that enables the underlayment to act as a thermal break, contributing to greater occupant comfort by helping make the floor warmer in the winter and cooler in the summer.

Similar to the acoustics ratings, manufacturers that provide products with strong R-values will showcase them on their literature and packaging so both the salesperson and buyer can easily see it.

5. Improve comfort during walking and standing. Underlayment with good compression resistance disperses the impact energy of footfall, reducing strain on knees and hip joints and affording more comfortable walking over the life of the floor.

Also, underlayment made specifically for use under glue-down or floating floors may provide the proper compression resistance to help minimize impressions and indentations that can occur. In addition, these underlayments can help laminate flooring sound more like real wood or tile when walked upon.

6. Some premium underlayments are made using recycled materials, helping preserve the environment by diverting post-industrial materials from landfill. In projects aiming for LEED certification, underlayment made from recycled content can contribute to the earning of LEED credits under the category of Materials and Resources.

There’s so much more a properly matched underlayment can do to help make the flooring system work for the end user’s benefit. These six examples, though, are key reasons why it is important for retail and commercial salespeople to better understand the properties of the various underlayments on the market so they can help their customers select the one that is best suited for the floor covering they are purchasing. A properly aligned flooring assembly will benefit everyone, especially end users who you can bet will share their experience with family, friends and colleagues.