Jack Mans, Plant Operatiions Editor -- Packaging Digest, 4/1/2013 10:48:05 AM Aerofil Technology Inc. (ATI) began its operations in Sullivan, MO, in the fall of 1988 with two small aerosol lines and less than 50,000 sq ft of space. Since then, ATI has greatly expanded and now serves clients around the world. Its capabilities, customer base and facility size Joe Sonderman (left) and Greg Wilke discuss features of the Spic n' Span bottle.ave grown exponentially during the past 25 years. Today, ATI is a Lean contract packager with a continuous-improvement culture with approximately 350 full-time employees and 16 production lines in a 400,000-sq-ft facility.

In 2007, ATI's ownership group (privately held) knew that, to remain competitive in today's fierce global economy it had to differentiate itself from its many competitors by being able to create a true value-added culture in which the entire supply chain would benefit. Robert Dunaway, CEO/owner, convinced his partners that ATI's adopting the philosophies and practices of the Toyota Production System (TPS) was vital to the company's long term success and has never looked back. "At ATI, the Aerofil Business System is no longer just another initiative, but a way of life and the culture of our entire workforce," says Dunaway.

At the outset of its Lean journey, the company immediately dedicated four of its top managers full time to both learn and implement the many learnings and processes of TPS that are now commonplace across the company today. Like anyone about to embark on a journey, they started by creating what is referred to as a Value Stream Map that documented their manufacturing processes and information flow from receipt of raw materials through the shipment of the finished goods to their customers. It was from here that other foundational tools such as 6S, Standard Work, One-Piece Flow and Pull Systems rapidly evolved.?

"Lean has had an immediate and dramatic impact on the entire workforce and culture since Day 1," says Pat Bergin, president. At the core of the learning, ATI focused on what it considers its most valuable resource. "Our most valuable and precious asset is not our equipment, it's not how many units we produced in a given day-it's our employees," says Bergin. Lean unleashed and empowered the organization's workforce from the CEO on down. It engaged every single employee throughout the entire enterprise, driving continuous improvement on a daily basis, according to Bergin.

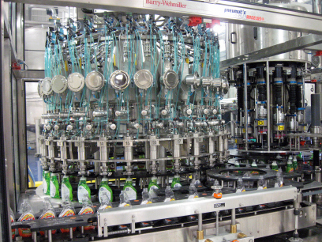

In the spring of 2009, ATI subdivided the company into smaller, more manageable business units, also known as Value Streams, with their own individual Profit & Loss. ATI identified that it wasn't doing as well as originally thought in its dry and granular business and decided to exit that Monobloc filler/capper includes a 30-head mass flow filler and a 12-head capper. The filler incorporates Coriolis technology that achieves 1-gm fill accuracy. category completely. It immediately began looking at the latest high-tech/high-speed liquid bottling line available in the marketplace. The new line, which started in October 2012, runs 15 different bottles with seven different closures, including trigger closures.?

In designing the high speed line, ATI first established the operational requirements for each piece of equipment on the new line and then used another Lean tool known as 3P (Production, Preparation, Process), which required seven different layouts at the outset of the project. Once the equipment was selected, the 3P Team literally placed full-size corrugated cutouts of each piece of equipment on the floor to determine the most suitable line layout.

"This let us get a good idea of how the equipment would fit in the room, and how accessible it would be for the operators," says Greg Wilke, who was the project manager for the installation and is now the production leader during start-up for the new line. The result is an efficient high-speed packaging line that is operated by only three people.

"Flexibility is one of our strengths, so the new line needed to be capable of running different bottle styles and closures," says Joe Sonderman, svp of operations. "Changeover was a paramount concern, because we have to get in and get out of different products in a timely manner."?

A major change that was instituted for the new line was that processing and packaging are in the same room, though they are in separately defined areas. "We have always located processing and packaging in separate rooms, but this new arrangement allows close interaction and effective communication between blending operators and line operators," says Sonderman.?

Dedicated line integration

As the planning for the new line progressed, systems integrator Advanced Packaging Integration became a key contributor. "We were initially contacted to bid on the robotic palletizer," says John Vaninger, vp-operations, "but as we got more involved in the project, ATI realized that we could do a lot more for them than the robotic palletizer." Advanced Packaging Integration provided the systems integration, supplying all of the conveyors and supplying the controls integration.

"ATI had a definite idea of what they wanted in the new line," says Vaninger. They wanted a U-shaped layout with the operators in the center. Because they are a contract packager and have to be able to run a variety of packages, they wanted the line to be as flexible as possible and require minimum changeover time.

Among Advanced Packaging Integration's tasks was to integrate the entire packaging line and the development of the controls. "We integrated all of the machines into one main processor and common HMI, which monitors the status of each machine and displays the status of each machine, as well as the OEE The labeler features four complete label stations arranged to apply the front and back labels without stopping for label changes. When a roll of labels runs out, the system automatically switches label stations on the same side of the machine allowing production to continue uninterrupted during label roll changes. (Overall Equipment Effectiveness), on the 60-inch overhead LCD scoreboard," says Vaninger. Each machine has its own dedicated controls and HMI, but these are also integrated into the main system.

Advanced Packaging Integration designed and built all of the conveyors along with required line devices that monitor bottle movement throughout the system. All of the bottle conveyors are equipped with quick-change guide rails to reduce changeover time, and all case conveyors are powered by 24-volt DC motors to minimize noise and energy costs.

Multiple vision systems were installed throughout the packaging line to ensure product quality at each stage of the filling and packaging. These are included at the exit of the unscrambler to ensure the bottles are oriented properly, at the exit of the labeler to ensure that no labels are missing and that labels are properly oriented, after filling and capping to ensure proper filling level and that caps are in place and are not cocked and after the case packer to ensure that cases are filled. Cognex supplied the cameras, and the controls are Allen-Bradley from Rockwell Automation to provide a common platform.?

Running 22-oz Spic and Span bottles

During Packaging Digest's visit, the line was running a 22-oz Spic and Span bottle with a handle and a trigger closure at a rate of 150 bottles/min. To start this operation, PET bottles are loaded into the floor hopper of a Posimat Posiflex 30-VA bottle unscrambler. The bottles are lifted to an overhead hopper on a cleated conveyor. The 24-pocket unscrambler has two bowls that rotate in different directions to achieve proper bottle orientation. The bottles leaving the unscrambler are conveyed on a vacuum conveyor to eliminate tipping. "A major reason that we selected the Posimat unscrambler is because the changeover from one bottle to another is so quick. Once the new bottle is programmed, it takes a push of the button on the HMI and toolless changeover of the orienter in minutes to perform the changeover," says Sonderman.

The bottles travel to a Pago Model 520 non-stop pressure-sensitive labeler that applies both front and back labels as well as wraparound labels. Sonderman says, "We label before filling, because there is less product waste if we have to discard a bottle because of a bad label."?

The Model 520 labeler was sold to Aerofil by DTM Packaging LLC, but American Fuji Seal Inc. has since purchased Pago. DTM is still the distributor for the labeler in the U.S.

The labeler features four complete label stations arranged for non-stop configuration to apply the front and back labels. When a roll of labels runs out, the system automatically switches label stations on the same side of the machine, allowing production to continue uninterrupted during label roll changes. The operator slides out the label head requiring a new label roll, makes the change and then slides the head back into position, ready to operate.

Sensors detect the bottles entering the machine and adjust the speed automatically. A wheel and chain alignment system separates and aligns the bottles for optimum positioning without the need for changeparts. An upper bottle hold-down belt holds the bottles in place during the labeling process.?

This belt is equipped with an adjustable air bladder that compensates for slight differences in bottle height. The main conveyor and hold-down belt are all servo driven and change speeds synchronously with the label applicators when the line speed is varied or when changing from one bottle to another. The labeler achieves a label placement accuracy of +/-2mm.

A Cognex camera inspects bottles as they exit to ensure proper label application. If an improperly labeled bottle is detected, it is ejected by an air blast. If three bad bottles in a row are detected, the machine shuts down and triggers an alarm.

Mono-block filler/capper

From the labeler, the bottles are conveyed to a Pneumatic Scale Angelus (PSA) mono-block filler/capper that includes a 30-head mass flow filler and a 12-head capper. The filler incorporates Coriolis technology from Micro Motion USA that achieves +/-1g fill accuracy. To meet ATI's explosion-proof requirement, the mono-block system is rated as intrinsically safe.

Product from the blending tanks in the adjacent processing area is The robotic palletizer HMI allows an operator to change over the palletizer in seconds, without change parts. The custom controls package allows new product patterns to be both added and adjusted via the HMI without the need of a PC. pumped to the hold tank installed next to the filler. Level and pressure control in the hold tank maintains a constant level in the tank to maximize fill accuracy. The product is then pumped to the 30 fill heads, each of which has its own supply tube, enabling each meter to act independently. The nozzles are designed for laminar flow to minimize splashing and aeration.?

Each nozzle is equipped with a diaphragm valve that features soft stop/start capabilities that allow the flow profile into the bottle to be adjusted to accommodate difficult items, such as foamy or high- or-low viscosity products. The Micro Motion system automatically tracks product viscosity and temperature and will sound an alarm if they are out of spec. The system, which includes a no-bottle/no-fill feature, tracks the fill of each bottle and will reject the bottle after it leaves the capper if the fill is low.

The filled bottles travel through a transfer starwheel into the 12-head capper that was chosen by ATI because it can run all types of closures, including trigger and pump caps as well as plug and screw caps. Trigger caps can be a challenge, and a sensor on the capper detects the opening on the bottle and a V-block system helps guide the quills into the bottle. The capper fully tightens the cap to a preset torque using magnetic torque control, eliminating the need for a retorquer.?

In response to ATI's diverse packaging requirements, PSA also supplied two integrated sorters to supply triggers, pumps, press-on and screw-on closures. Quick SKU changeovers are efficiently accomplished with PSA's Zepf Mark II, No-Tool container handling parts in conjunction with a recipe driven, motorized turret-height adjustment feature.?

"Here again, flexibility was essential," says Sonderman. "This capper allows us to efficiently run every kind of closure we have on the market with minimal changeover requirements. Pneumatic Scale Angelus's solution for not only applying triggers and pumps but also a variety of caps on the same platform was a key reason they were selected."?

Integrated controls

The filler/capper is controlled from a single operator station. The PLC-based controls architecture is configured with simple recipe-driven parameters that track and display the weight, temperature and density for each bottle filled.

A user-friendly touchscreen interface allows each filling head to be monitored, sampled and adjusted. And because each mass-flow meter houses its own control package, each meter can be adjusted independently. Product recipes can be created and edited, and rejection parameters for out-of-spec containers can be set as well. Real-time and historical shift data can be viewed on-screen and printed. And the programmable logic control-based technology makes system diagnosis and servicing easier.

The touchscreen also simplifies capper adjustments. The touchscreen interface allows operator control of all capper functions and displays diagnostics. Optional recipe height adjustment offers instant, push-button container height changeover.

A Cognex system at the exit of the capper looks for cocked caps or missing caps or no quills, and rejects those bottles. QC personnel collect samples from all heads once an hour to ensure that there are no undetected problems.?

Versatile case packer

The line at ATI is arranged in a U-shape, so bottles leaving the capper make a right turn and then travel along an accumulation conveyor before making another right turn to travel through the downstream equipment.

They travel through a PB inkjet printer from Hitachi America Ltd. that applies a lot code on the back side of bottles below the label. Bottles continue through an Enercon Industries Corp. Super Seal induction sealer.?

Next the bottles enter a Hartness Intl. Inc. Model 835 case packer. As with all of the equipment, flexibility was paramount with quick and simple tool-less changeover. The Model 835 efficiently handles glass, plastic, cans and paperboard in both round and non-round configurations with containers of various sizes. It also handles a variety of secondary packaging formats including RSC cases, trays and display trays.?

Bottles enter the case packer single file before a swinging gate diverts The wrapper features patented NO-THREAD powered pre-stretch technology in which the system essentially threads itself without operator intervention and which stretches the film to twice or more its stationary length as its being wound round the pallet to reduce film usage. them into lanes. The unit was running the Spic and Span bottles in four lanes for 12-pack cases, but it can run up to six lanes, which ATI uses to pack 18-bottle cases. It can also pack multiple cases simultaneously for high-speed requirements.

The packer features a patented "air transfer" system that provides low-pressure container handling that offers gentle conveyance and packaging of lightweight and unconventionally shaped containers.?

ATI installed a Model 330 adhesive case erector/bottom sealer from A-B-C Packaging Machine Corp. to erect the cases for the packer. The continuous-motion unit features PLC electronics with touchscreen controls for operation, documentation and diagnostics. A Cognex camera looks down into the finished cases leaving the case packer to ensure that no bottles are missing, after which an A-B-C Packaging Machine top sealer tapes the cases shut.?

The cases travel past a ProSeries printer from Foxjet, an ITW Co., that prints a lot code and other information on the cases, and the cases then travel up a Ryson Intl. Inc. spiral conveyor to an overhead conveyor that transports them to the warehouse.?

There the cases are palletized with an IRB 660 robot from ABB Inc. that is programmed by Advanced Packaging Integration. The palletizer HMI allows an operator to change over the palletizer in seconds, requiring no changeparts to switch to any of ATI's many products. Advanced Packaging Integration's custom controls package allows new product patterns to be both added and adjusted via the HMI without the need of a PC.

The pallets are conveyed to a Wulftec Intl. Model WCRT175 stretch wrapper, where an arm rotates around the stationary pallet and applies the film. The arm starts at the bottom, rises to the top and then goes back down to the bottom of the pallet, so there is a double layer of film applied.

The wrapper features Wulftec's patented No-Thread powered pre-stretch technology in which the system essentially threads itself without operator intervention. It stretches the film to twice or more its stationary length as its being wound to reduce film usage.

The wrapped pallet is then conveyed past a Model 250 print-and-apply labeler from ID Technology, div. of Pro Mach, that applies a corner-wrap label.?

The future

As ATI looks to its future, Lean is clearly the dominating driving force for the company's culture. "It is our way of life," says Bergin. "We are steadfast in our convictions that it's our employees that are the 'real experts' who guide us in our continuous-improvement processes daily. They were involved from the very beginning of the high-speed liquid line from design, to development, to the FAT [factory acceptance test] to the final implementation and are the true keys to ATI's long-standing success."

Sidebar Changepart storage protects and delivers With the multitude of containers that are run on the new line and m

An automated vertical storage unit with 38 shelve stores all of change parts at Aerofil. To retrieve an item, the operator enters the item name into the HMI, and the system automatically delivers the appropriate tray to the delivery space.ore that will be added, storing and keeping track of the changeparts for all of the equipment loomed as a significant challenge. Ingeniously, ATI installed a Shuttle XP500 vertical storage unit with 38 shelves from Kardex Remstar LLC to store all of its changeparts.?

Horizontal shelves are arranged vertically along the front and back of the unit. When the item on a shelf is required, the shelf is moved onto a belt system that transports it down the center of the unit to the opening at the front, where the item is automatically presented to the operator.

The Shuttle XP is a fully automated system. When an item is first placed into the unit, the operator identifies the tray number on the control panel and the system remembers the location. To retrieve an item, the operator enters the item name, and the system automatically retrieves it.?

The plant uses carts to move the changeparts between the storage facility and the equipment on the packaging line.

"The Kardex system has worked out very well for us," says production leader Greg Wilke. "It doesn't take up much floor space for the amount of storage it provides, and it allows us to easily keep track of all of the changeparts. Also, it eliminates any damage that might occur if the parts were sitting out on racks."