Global process control and yield management product leader KLA-Tencor’s newly launched Taiwan Training Facility continues to reflect the market’s important role in the company’s business strategy.

New Taiwan training facility

The newly opened Taiwan training facility will offer the same training courses as the company’s other global training centers in Singapore and U.S., said Chief Marketing Officer Brian Trafas during the opening ceremony of the new training facility held at the company’s Hsinchu branch on May 23, 2014.

The center especially designed to meet Taiwan market demands will also function as a training site for other Asian countries. “Most of the (center’s) use will be for Taiwan customers about 80 percent, with about 20 percent for other Asian customers,” said the company Chief Executive Officer Rick Wallace. The main aim of the center is to cater to Taiwan client demands for more convenience and local technical support.

Aside from serving for external training purposes, the center will also cover internal training, said Efren Lopez, Sr. Director, of the company’s Learning and Knowledge services. KLA-Tencor’s wafer detection or metrology equipment training courses for engineers can range from one to six weeks. Engineers can learn hands on how to operate and carry out basic equipment maintenance and repairs.

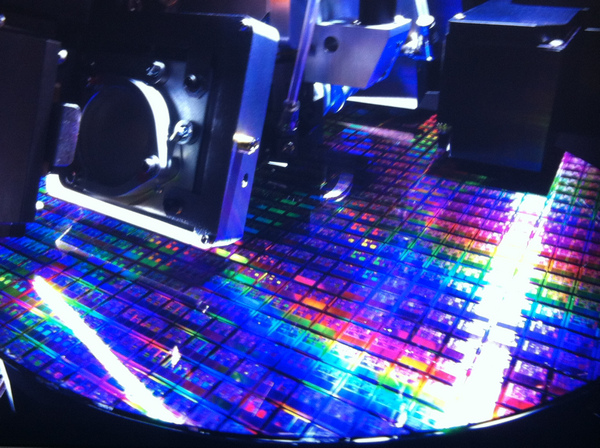

A poster image of a KLA-Tecor semiconductor wafer defection device at the training center. The device uses optic technology to identify wafer defects. (LEDinside)

Taiwan market continues to dominate company revenue

A breakdown of company revenue shares sheds light to the importance of the Taiwanese market for KLA-Tencor. The country has been the company's largest market for four consecutive years, said Trafas. According to the company’s 2013 financial report, Taiwan consisted 33 percent revenue share totaling US $936.46 million followed by the U.S. market 30 percent of US$ 846.12 million, and Japan’s 11 percent US$ 311.21 million.

Taiwan’s talent pool is also crucial to the company’s daily business operations. The Taiwan office is home to about 480 employees that acts manpower for the company’s U.S. office. The office is involved in important work, providing mostly for R&D roadmap, said Wallace. “KLA-Tencor continues to consistently expand Taiwan’s R&D (department), and plans to expand by roughly 8 to 10 percent,” said Norman Chang, President of the company’s Taiwan office. “We expect to add 30 to 50 staff in Taiwan this year.”

KLA-Tencor is a provider process control and yield management solutions, that incorporate nspection and metrology technologies applicable to the semiconductor, data storage, LED, and other related nanoelectronics industries. The company recently released a new reticle qualithy control solution Teron™ SL650, a new reticle quality control solution for IC fabs that supports 20nm design nodes