The main challenge faced today by PET plant manufacturers and operating companies alike is the sourcing of screen changers combining both the smallest footprint and the largest filtration surface in one single package.

Maag has developed tailor-made filtration units in close co-operation with Uhde Inventa-Fischer for an expansion project at a major facility in the Middle-East.

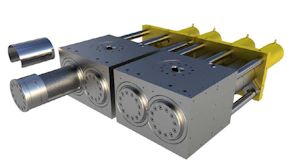

Completed with much fanfare in 2012, the customer’s additional manufacturing facilities are no strangers to superlatives. With a total additional capacity of half a million tons of PET bottle grade resin per annum, the plants have seen the deployment of the largest Melt-To-Resin reactors in existence, with Maag also providing a complete range of melt pump equipment. The reactors are now joined by a number of continuous screen changers, whose uniquely arched filters (patent pending) maximize the filtration surface available, which guarantees a very low melt residence time, especially in high viscosity resin applications, yet they incorporate a compact footprint.

Maag pioneered the production of supersized screen changers with a world-first delivery for virgin polymer production taking place no less than six years ago. Those were equipped with candle filters and reduced the residence time of the resin to less than 30 seconds, a feat which could not previously be achieved with large area filters.

The company has kept pushing the envelope ever since. Arched filters are a logical development based on the same technology, but utilize “one way filters”, that can be disposed of after use. This in turn eliminates the entire process of cleaning the candle filter bundles, which normally involves vacuum ovens, acids, solvents and subsequent bubble point tests to determine if the filters are still useable.

Ueli Thürig, Maag’s CEO comments: “Though duplex and simplex filters are still widely used, piston-based screen-changers are a natural, cost effective addition to Maag’s portfolio, and they meet the increasingly technical demands of our customers. As for the adoption of arched screens it allows manufacturers to dedicate 75% of the surface of the cylinder to filtration. Finally, and contrary to traditional breaker plates facing each other, our very smart design also permits straight pump connections that reduce the investment further with no need for additional pipe work”.

Changeovers now take less than 10 minutes, with only one operator, without requiring cranes or complex tools, thus guaranteeing constant operation of the system from process to process. Flexibility is also reflected in the fact that, depending on the melt contamination (solid or gel), the screens can be made out of Woven Wire Mesh (WWM) or Fiber Metal Melt (FMM).