Osram Opto Semiconductors GmbH of Regensburg, Germany claims that it has achieved one of the best values in the world in terms of forward voltage for blue high-current chips, leading to an increase in efficiency of up to 8%.

Optimized indium gallium nitride (InGaN) chips featuring Osram's UX:3 chip technology are the basis for blue or white LEDs, and are already used in production. The firm also sees considerable potential for reducing forward voltage by a further 20-30mV by the summer, offering a further boost in efficiency.

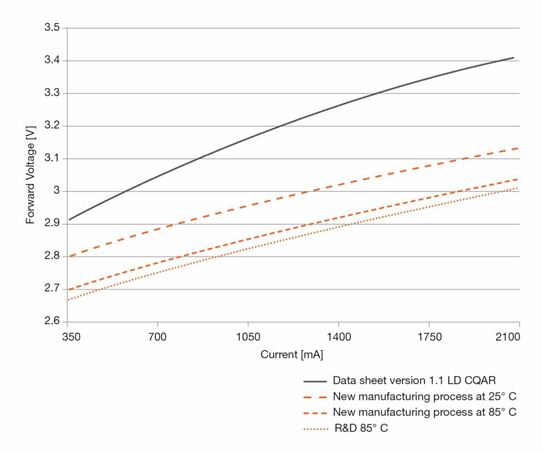

Picture: Forward voltage versus current for Osram's optimized LED, compared with the data sheet for the previous Oslon Square (LD CQAR) LED.

The blue Osram Oslon Square (LD CQAR), for example, now has a typical forward voltage of only 2.87V instead of the 3.05V specified so far in the data sheet – the lowest typical values in this component class worldwide, it is reckoned. At 85°C a voltage of 2.78V can be achieved. Depending on the operating point, this translates into an increase in efficiency of these LEDs of 6-8%, which can be transferred to the entire UX:3 chip family, which can be found in all blue and white LEDs. The LEDs are used in a wide range of applications – the Oslon Square, for example, in street lighting and industrial lighting.

"The reduction in forward voltage was achieved thanks to a new process in the epitaxy," says project manager Dr Marcus Eichfelder. Production of the first optimized chips started last August.

"In the laboratory we have already succeeded in further reducing the forward voltage by as much as 30mV," says Dr Joachim Hertkorn, Epitaxy expert at Osram Opto. This would improve efficiency of the LED chips by a further percentage point. "In view of the speed with which this first step has been implemented, we are confident that the improved process can be transferred to production by the summer," he adds. "Any further reductions in forward voltage will then only be marginal owing to the laws of physics.