Researchers based in Japan claim the highest output power and external quantum efficiency (EQE) so far for deep ultraviolet (DUV) sub-270nm-wavelength light-emitting diodes (LEDs) during DC operation [Shin-ichiro Inoue et al, Appl. Phys. Lett., vol106, p131104, 2015]. One 265nm device achieved 90mW output power and 6.3% peak EQE. The team from Japan's National Institute of Information and Communications Technology (NICT) and Tokuyama Corp used photonic crystal and subwavelength structures to enhance light extraction, giving improved EQE performance over previous devices.

Potential applications for DUV LEDs include air/water purification, surface disinfection, bio-agent detection, lithographic microfabrication, and medicine. To replace mercury lamps, high-power, efficient operation is required, particularly in the sub-270nm region needed for efficient destruction of DNA and RNA for microbial sterilization. However, existing DUV devices have low EQEs – in the 270-300nm range a value of 10% has been achieved, but moving to shorter wavelengths yields a dramatic drop off in efficiency. For comparison, blue LEDs have reached more than 80% EQE.

DUV LEDs are generally constructed from aluminium gallium nitride (AlGaN) materials, which suffer from high defect densities in active layers and poor light extraction efficiency. Defect densities can be reduced by growing AlGaN epitaxial layers on AlN rather than sapphire substrates.

AlGaN DUV LEDs use p-GaN contacts to give a reasonable electrical contact. Unfortunately this means that the device must be flipped so that the light is emitted from the back-side/substrate of the device, since GaN strongly absorbs DUV radiation. Devices on sapphire already suffer from poor light extraction due to total internal reflection at the sapphire-air interfaces as a result of the difference in refractive index at 265nm (1.8:1). This contrast is made worse with AlN substrates (2.29:1).

The NICT/Tokuyama team produced a 100μm transparent AlN substrate by hydride vapor phase epitaxy (HVPE) on c-plane single-crystal AlN, grown by physical vapor transport (PVT). The HVPE AlN was separated from the PVT AlN since the latter absorbs DUV. The PVT AlN was removed using polishing techniques.

The epitaxial layers for the DUV LED were grown by metal-organic chemical vapor deposition (MOCVD) on the free-standing HVPE AlN: 100nm AlN, 1μm silicon-doped n-Al0.75Ga0.25N, three-period multiple quantum well (MQW) active region, magnesium-doped p-AlN electron-blocking layer, p-Al0.8Ga0.2N cladding layer, and p-GaN contact. The contact layer was chosen so that good ohmic electrical contact could be made with the metal electrode and for current spreading, despite the strong DUV absorption of p-GaN.

The fabricated LEDs had ~0.001cm2 mesa regions and, respectively, nickel/gold and titanium/aluminium/gold p- and n-type electrodes.

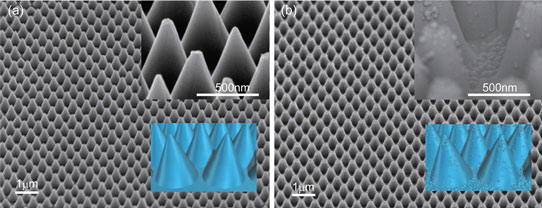

The majority of light was designed to be emitted via two-dimensional photonic crystals on the AlN surface to improve light coupling between the semiconductor and air. The triangular-lattice photonic crystal (Figure 1) was formed using inductively coupled plasma etch. The elements of the lattice consisted of circular cones of AlN. The lattice spacing was in the range 250-1000nm. Experiment and simulation gave an optimal spacing of ~600nm, giving 144% light extraction enhancement over a flat surface.

Figure 1: SEM micrographs of fabricated light extraction structures on AlN substrate surfaces: two-dimensional photonic crystals with triangular lattice of circular AlN cones, (a) without subwavelength nanostructures and (b) with subwavelength nanostructures. Insets show enlarged SEM images and schematics.

Light extraction was further enhanced with self-organized subwavelength 30nm-diameter hemisphere nanostructures produced through wet etching with hydrochloric acid. A hybrid structure of photonic crystal and subwavelength structures achieved 196% light extraction enhancement with 300nm lattice spacing.

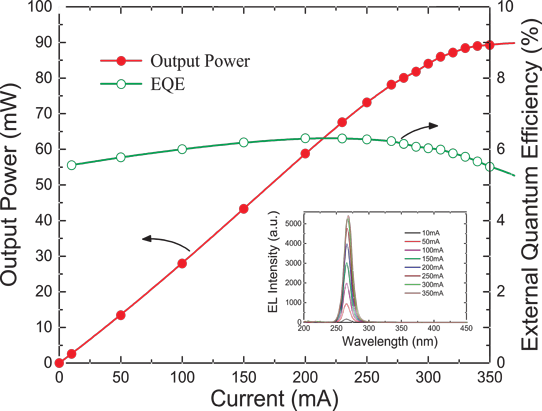

Figure 2: Output power and EQE as function of injection current for 265nm DUV-LED during DC operation. Inset shows EL spectra.

Electroluminescence was measured up to 350mA injection current with the device encapsulated on an AlN submount (Figure 2). The maximum output power was 90mW with external quantum efficiency of 5%. At 200mA, the output power was 59mW with 6.3% EQE. The researchers write: "This is the highest output power and EQE published to date for DUV-LEDs with a peak emission wavelength shorter than 270nm during DC operation."