DAS Environmental Expert GmbH of Dresden, Germany, has developed SALIX, a point-of-use system for removing waste gas pollutants in semiconductor wafer manufacturing wet bench applications. This solves a common problem where gases from the solvents, acids and alkaline materials used in wet processing combine to form a powder in the exhaust line. This powder can be a "toxic bomb" according to Dr. Horst Reichardt, CEO and president of DAS, or at least cause throughput and cost issues since the exhaust may have to be cleaned every one to two days.

The single-wafer cleaning process widely used for cleaning 300-millimeter wafers in wet benches distributes cleaning agents onto rapidly spinning single wafers and spins them off at the edge where baffle plates within the system collect the water, acidic and alkaline chemicals, and volatile solvents (the process for cleaning 200-millimeter wafers immerses the entire cassette). A large fab may have 20-30 such wet benches. With up to 12 stations per wet bench and exhaust from each chamber requiring several exhaust systems, the SALIX scrubber eliminates the need for elaborate change-over modules to avoid deposition in the pipes. It is more cost-effective and efficient at preventing clogging than conventional approaches used to separate and extract the acids, alkalines and solvents in the exhausts which require separate suction to prevent particle buildup and condensation within the pipes.

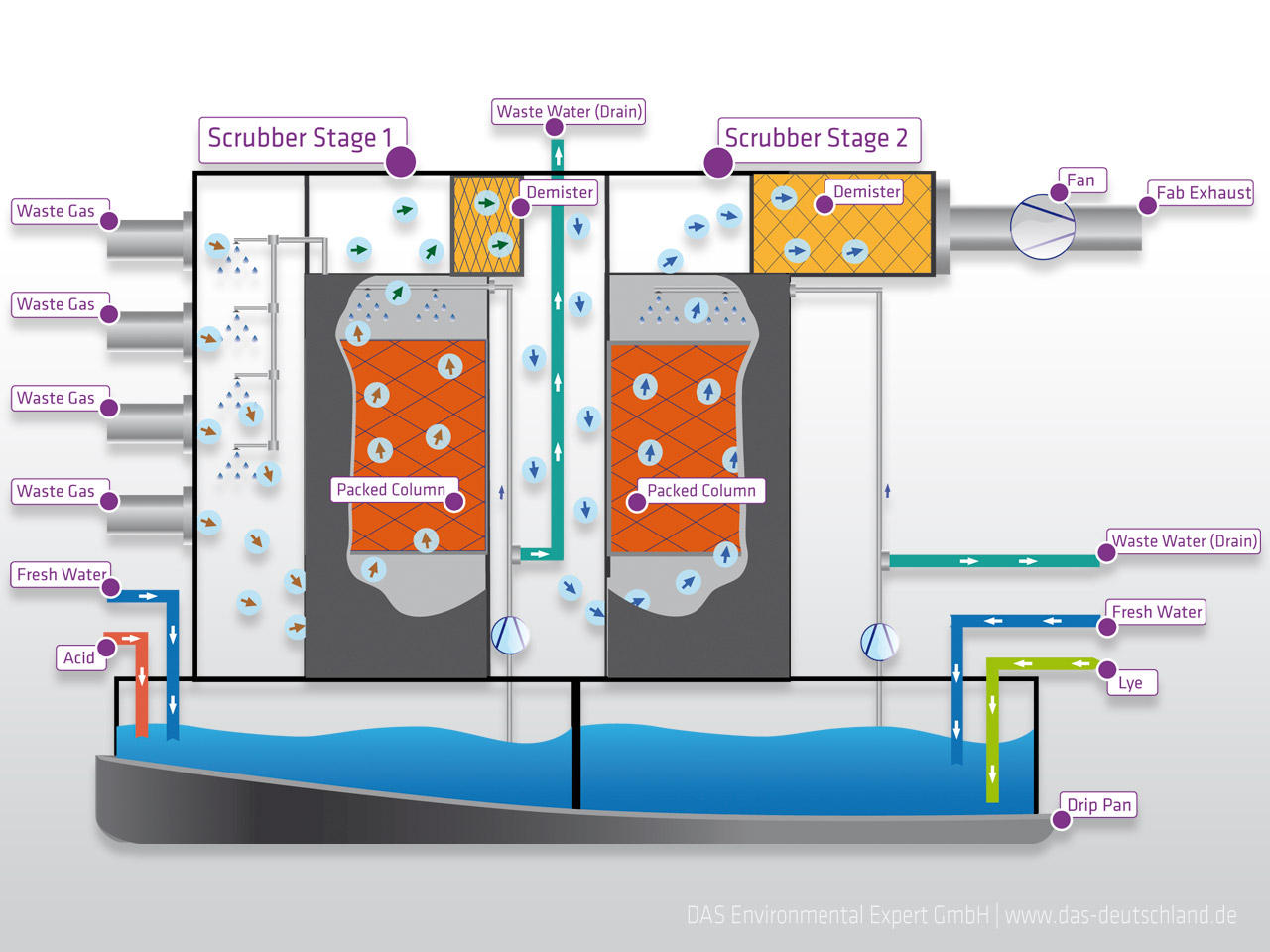

In contrast, SALIX removes the harmful substances from the gas stream directly at their point of origin using a two-stage scrubber process of chemical and physical absorption, and can treat up to 3600 m3/h of raw gas. Separate inlets feed the harmful gases from the wet bench process chambers into a SALIX pre-scrubber that pre-cleans the gas using spray nozzles. Next the waste gases pass into the first scrubber stage and then a second stage that uses a different scrubbing liquid. The remaining clean gas then can be released safely into the air without any danger to the technology or the environment. Because the SALIX system does not require any air dilution, the clean air remains in the clean room, further reducing cost.

Dr. Guy Davies, director of the Waste Gas Abatement business unit at DAS Environmental Expert explained, "When a global foundry based in Taiwan came to us seeking a better solution to treat water-soluble exhaust gases from a wet bench application, we installed SALIX as a first-of-its-kind point-of-use system. It has been running there since January of this year and, after six months of operation, emissions measurements show zero harmful substances in the exhaust. One SALIX system per wet bench is all that's needed, and just one pipe for the cleaned exhaust. Salix "offers a smaller footprint with no switching boxes needed, and is far more cost-effective and efficient than central scrubbers for treating processes that create water-soluble waste gases. We believe our proven SALIX solution, which is SEMI S2 international and German TA-Luft standards compliant, opens new markets for point-of-use scrubbers in the semiconductor, LED, PV and FPD industries. In fact, we have seen increasing interest in SALIX and already have received multiple inquiries from U.S. customers. In addition, we are using the evaluation results for further process-based optimization and have developed a custom fit bypass function that will enable production to continue with no interruption.

DAS also announced it has added Technica, U.S.A. as a new local service partner to deliver faster response time for service and maintenance for U.S. customers.