Structured Materials Industries Inc (SMI) of Piscataway, NJ, USA, which provides chemical vapor deposition (CVD) systems, components, materials, and process development services, says that its temperature profiling flange is a versatile tool for in-situ optical pyrometry profiling of CVD deposition planes, adding that achieving good temperature uniformity across the deposition plane is essential to optimizing CVD growth uniformity.

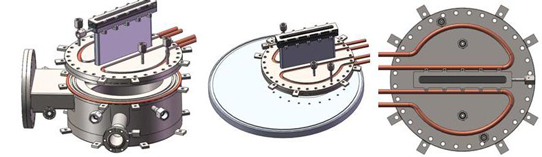

The temperature profiling flange is compatible with SMI's Epic and Legend series reactors and is designed to be easily adapted to a variety of Emcore/Veeco MOCVD reactors (D180, D125, E300, E400 etc) or other custom reactors (with offset adapter plates or custom sizes). It is also compatible with a variety of optical monitoring tools including pyrometers, optical growth rate monitors, as well as k-Space and LayTec in-situ monitors. The temperature profiling flange's quartz viewport offers angled or direct perpendicular optical access to platters as large as 7" OD (outside diameter) or, with offset mounting, the same flange can service multiple reactor sizes with adapters. Alternatively, larger custom versions can be fabricated.

Picture: Temperature profiling flange shown on an SMI Epic series chamber (left) and on an offset flange for a larger E300 tool (center) top view of the temperature profiling flange, with central viewport, water-cooling line, and gas delivery ports (right). Note the large optical clearance for unencumbered observation. ?

Water-cooling lines protect the flange's differentially pumped double O-ring seal, allowing the flange to monitor platter temperatures up to 1200°C in most operating conditions. Additional water cooling of the viewport is required to allow operation through 1600°C platter temperatures.

The flange contains two gas delivery ports, and has mounting points for a perforated gas distribution plate to disperse the gas to simulate a uniform flow. Adapter tubing is required to go between the standard gas line plumbing and the temperature profiling 'showerhead'.

Product specifications include: stainless-steel 304 flange/O-ring or metal sealed versions as standard; an O-ring sealed quartz viewport (with other materials available) that can be given 5° angle to reduce beam scatter; rated to measure platter temperatures up to 1200°C, or 1600°C with optional optical port water cooling clamp-on plates. Options include: custom flow flange adapter plumbing; in-situ/pyrometer adapters; and other angles.