Agilent Technologies Inc of Santa Clara, CA, USA has announced several innovations for the 2014 release of its suite of device modeling and characterization software tools. The suite comprises the Integrated Circuits Characterization and Analysis Program (IC-CAP), Model Builder Program (MBP), and Model Quality Assurance (MQA) software of Agilent EEsof EDA (which supplies electronic design automation software).

IC-CAP software is a device-modeling program that delivers characterization and analysis capabilities for the latest semiconductor modeling processes. Providing efficient and accurate extraction of active device and circuit model parameters, IC-CAP performs modeling tasks including instrument control, data acquisition, graphical analysis, simulation and optimization. It is used by foundries and design houses to characterize foundry processes.

MBP is a one-stop solution that provides both automation and flexibility for high-volume, high-throughput device modeling. It includes built-in characterization and modeling capabilities as well as an open interface for modeling strategy customization. It is widely used both by foundries and design houses to extract and customize SPICE model libraries.

MQA provides a complete solution and framework to fabless design companies, IDMs and foundries for SPICE model library validation, comparison, and documentation. It performs model QA, comparison, and documentation automatically to ensure design success using advanced process technologies, says Agilent.

“Over the past few years, we’ve steadily expanded our device modeling platform through internal development and acquisition of key technologies,” says Brian Chen, Agilent’s device modeling planning manager. “This marks the first release of our entire portfolio and represents a significant advancement toward our vision of being a partner that uniquely delivers a complete end-to-end, measurement-to-modeling solution.”

Advanced modeling capabilities

The new software release features three advanced device modeling packages for Agilent’s DynaFET, BSIM6, and BSIM-CMG models.

BSIM6 is the industry-standard model for bulk MOSFETs, offering key improvements for analog/RF applications over its predecessor BSIM4. BSIM-CMG is the industry-standard model for sub-20nm 3D FinFET technologies. Modeling solutions for both BSIM6 and BSIM-CMG in the 2014 release are designed to help the semiconductor industry understand and use these new technologies.

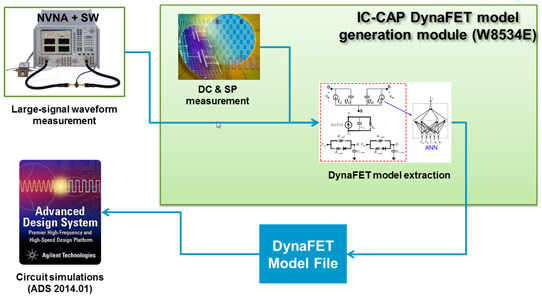

Picture: The DynaFET model extraction package, an integral part of Agilent’s GaN HEMT characterization, modeling and simulation solution.

The DynaFET modeling package is based on internally developed technology and is an integral part of Agilent’s gallium nitride high-electron-mobility transistor (GaN HEMT) characterization, modeling and simulation solution. The GaN HEMT modeling package provides a GUI-based turnkey solution for DynaFET model generation.

Using artificial neural networks for charge and current formulations, and incorporating trapping/de-trapping and self-heating effects, the time-domain DynaFET model is capable of fitting accurately to DC, linear and large-signal measurement data — all simultaneously. This allows a single model file to be used for the design of different applications under various bias conditions, all with accurate simulation results, says Agilent.

Additional enhancements

The 2014 device modeling and characterization software release also provides new and enhanced features designed to improve productivity across the end-to-end work flow of device characterization, model generation and model validation. These enhancements include:

a programming editor; faster simulation speed with major simulators; expanded mismatch and variation modeling solutions; and a streamlined and flexible user interface to create, manage, monitor, and debug measurement test plans.

Agilent’s 2014 device modeling and characterization software release will be available in July.