Bosch Packaging Technology has expanded its portfolio for the serialisation of pharmaceutical packaging to help drug manufacturers comply with potential legislation changes about to be introduced by governments round the globe in the fight against counterfeit drugs.

Implementation of legislation changes is in the offing as countries unite for the fight against counterfeit drugs for a stricter labelling of pharmaceuticals, leading to demand for safer and more flexible solutions.

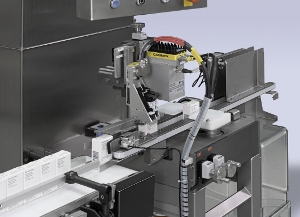

Carton Printing System (CPS) from Bosch, which is the foundation for all serialisation solutions from Bosch has been upgraded to meet the new requirements. Bosch has adapted the proven automation technology from its automotive sector to the specific requirements of the pharmaceutical industry.

The CPS system can print 1D or 2D data matrix codes on up to 400 folding cartons per minute, while both codes can be checked on different carton qualities thanks to an upgrade of the camera system.

The system automatically sorts out the products if the contrast and readability of the data matrix codes do not conform with the required level of quality. Easy to operate from the front, the machine's mechanical components are easily and quickly accessible in case of format changes.

An optimised threading of the labelling tape reduces downtime of the CPS 1900 to a minimum.

The CPS systems can be connected to both machine software and company IT in a multi-level process, ensuring that serial numbers are attributed reliably.

Bosch Packaging Technology product manager Daniel Sanwald said: "With our serialization concept, we offer customers more than just a machine. Bosch offers the complete package, which also includes the corresponding IT.

"This experience enables us to offer our customers IT solutions that not only process the entire order management; they also control both import and export of the serial numbers."

Depending on country and guideline, the numbers are either allocated centrally or generated by the company. Contract manufacturers in turn receive the numbers from their clients.

According to Sanwald, "our IT system is equipped for all three cases. The Bosch machines can also be flexibly combined with systems from other IT providers."

The IT concept offers other advantages for production companies like clear visibility for production parameters and data of all packaging lines.

"For instance, in the case of unforeseen events like downtime or modification, capacities are automatically re-planned. The connection of our machines with the corresponding IT offers companies a new production foresight."

This year, new guidelines will be in force in Saudi Arabia, where drug packaging must be equipped with a data matrix code step by step, followed by serial numbers in 2016.

In Brazil, individual batches must be serialized as of 2015, before it becomes obligatory the following year.

The U.S. Food and Drug Administration (FDA) is also gearing up to implement a standardised identification for all prescription drugs in form of a 2D data matrix code in a step-by-step approach until the end of 2023.

The European Union's Falsified Medicines Directive 2011/62/EU stipulates coded packaging with a 2D data matrix code and a unique serial number for nearly all prescription drugs, presumably from the first quarter of 2018.

Image: The CPS (Carton Printing System) forms the basis of all serialization solutions from Bosch. Photo courtsey of Bosch.