Due to new components, power electronic converters for power engineering applications are becoming even more efficient. In particular, silicon carbide (SiC) devices enable the construction of extremely efficient and compact power electronic systems. Now, Fraunhofer Institute for Solar Energy Systems ISE in Freiburg, Germany has successfully implemented silicon carbide (SiC) devices with a blocking voltage of 10kV in a DC-DC converter for medium-voltage applications, presenting a demonstrator that can be used in renewable power plants.

SiC devices with blocking voltages of up to 1700V have been commercially available for some time. Now research is focusing on SiC with even higher voltages and lower switching losses. The first prototype devices have already been developed. “In the past we have experienced significant success in the implementation of SiC semiconductors in power electronic systems for the low-voltage range, ” says Dirk Kranzer, group leader of Advanced Devices and Technologies at Fraunhofer ISE. “The logical step for us was to use these 10kV devices for medium-voltage applications,” he adds. “With this step, entirely new power electronic system structures become conceivable, supporting renewable power generation in large plants and power transmission in the next-generation energy grid.”

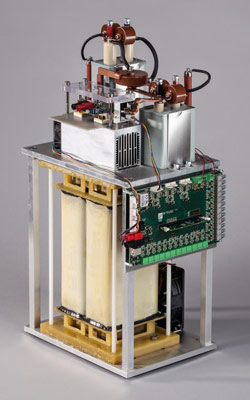

Picture: A 30kW medium-voltage DC-DC converter, developed at Fraunhofer ISE, containing 10kV SiC devices.

Fraunhofer ISE developed the first SiC-based demonstrator for the medium-voltage range within the Fraunhofer-Gesellschaft’s project ‘Supergrid’. The 30kW DC voltage converter with 3.5kV input voltage and 8.5kV output voltage reached an efficiency of 98.5%. The switching frequency is 15 times higher than that possible for conventional silicon devices within the same voltage range, it is reckoned. The SiC semiconductor devices used in the Fraunhofer‘s DC-DC converter circuitry were developed by Cree Inc of Durham, NC, USA.

Fraunhofer ISE says that the new high-voltage devices not only enable better efficiencies and more compact designs with fewer components but also facilitate totally new applications in power engineering or the rail industry. “We have a long road ahead until we are able to build converters with these silicon carbide devices which are ready for series production,“ says Fraunhofer ISE development engineer Jürgen Thoma. “With the new high-voltage devices and circuit design challenges, we encounter limits related to the insulation and construction techniques. This is especially evident with the even higher blocking voltages foreseen for SiC semiconductors in the future,” he adds. “Despite this, the time is now right to get a move on near-industry research using these promising new devices in power electronic applications for the power engineering of the future.”