The challenge in terms of sustainability:

The glass production is a very energy intensive process, where a large part of the spent fossil energy, which is necessary for the melting process, is emitted to the atmosphere again without being used.

To reach the aimed climate protection targets and reduce the raising energy costs, the glass industry is trying stronger than ever for an energy efficient glass production process.

The initial situation:

The aim is to optimize the glass production process in a way that energy consumption is reduced as far as possible.

Over the years the glass industry has optimized many process steps regarding the energy efficiency. Nevertheless in the area of the rejected heat by the waste

gases there is still a significant potential of thermal energy, which ends up unused in the atmosphere.

The solution - the sustainable technology/sustainable project/sustainable service:

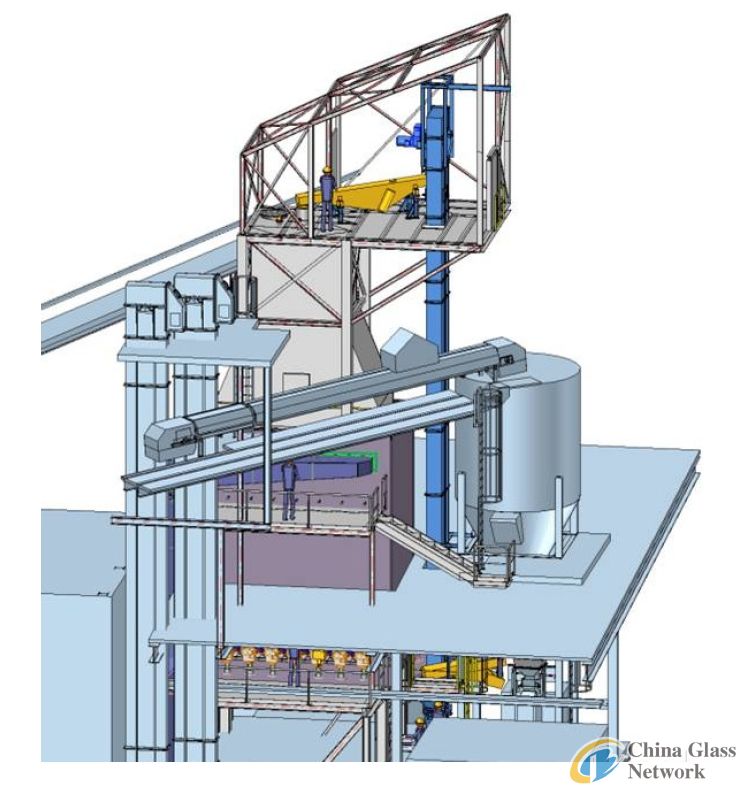

Amongst other activities in the plant construction sector for the glass production the company ZIPPE works in the field of batch preparation and cullet handling. Already some decades ago, ZIPPE has built the first batch preheaters with a high recycling cullet portion and sold them successfully. ZIPPE could steadily develop its preheating technology and adapt it to the different batch formulas of the single glass types thanks to the collected experience. Also, preheaters that run independently from the cullet portion are now available.

The sustainable strengths:

For the operator of a production process it is necessary to follow-up the process steps integrally, starting with the entrance of the raw material up to the outgoing of the final product and to optimize the corresponding processes in a way that a maximum of productivity is reached with the least effort regarding raw materials and waste material. Therefore the company ZIPPE always observes the whole process in its field of activity in the glass industry and tries to plan the different cycles energy efficient, low-maintenance and this inexpensive for the operator.

The advantages of batch preheating are:

Reduction of the emissions (CO2 and NOx)

Increase of the energy efficiency

Increase of the plant productivity

Facts:

The savings in concrete numbers:

10 - 15 % economy of fossil combustibles and / or electrical energy

Increase of the furnace tonnages

The relevant BLUecoMPETENCE topic areas:

The innovation described…

...increases energy efficiency.

...conserves scarce resources.

...minimises emissions.

...avoids or makes use of waste materials.