Bulletproof glass (also known as ballistic glass, transparent armor or bullet-resistant glass) is a type of strong but optically transparent material that is particularly resistant to being penetrated when struck by bullets, but like all other known materials, is not completely impenetrable. It is usually made from a combination of two or more types of glass, one hard and one soft. The softer layer makes the glass more elastic, so it can flex instead of shatter. The index of refraction for both of the glasses used in the bulletproof layers must be almost the same to keep the glass transparent and allow a clear, non-distorted view through the glass. Bulletproof glass varies in thickness from three-quarter inch to three inches (19mm to 76mm).[1]

Another construction method, which is becoming popular rapidly, is the use of security laminates as a film on the inner surface of ordinary glass. This, when bonded with the application of a pressure sensitive adhesive and cured fully, also provides a protection similar to the multi-layered bullet-resistant glass. The optical clarity is much better and tint-free, thickness and weight are reduced as much as 50–70%, and the process can be done as a retrofit on existing windows.[citation needed]

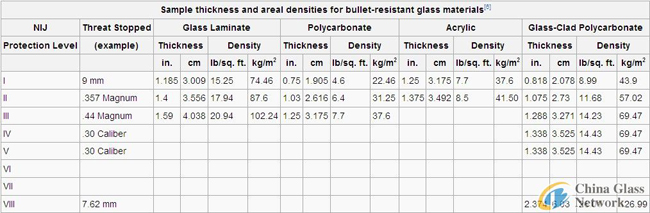

ConstructionBullet-resistant glass is usually constructed using polycarbonate, thermoplastic, and layers of laminated glass. The aim is to make a material with the appearance and clarity of standard glass but with effective protection from small arms. Polycarbonate designs usually consist of products such as Armormax, Makroclear, Cyrolon, Lexan or Tuffak, which are often sandwiched between layers of regular glass.[2] The ability of a glass itself to withstand shock is improved by the process of tempering. When treated with heating and cooling or with chemical processes, the glass becomes much stronger. The polycarbonate usually has one of two types of coating to resist abrasion: a soft coating that heals after being scratched (such as elastomeric carbon-based polymers) or a hard coating that prevents scratching (such as silicon-based polymers).[3] The plastic in laminate designs also provides resistance to impact from physical assault from hammers, axes, clubs,crow bars and so forth. The plastic provides little in the way of bullet-resistance. The glass, which is much harder than plastic, flattens the bullet, and the plastic deforms, (hopefully) absorbing the rest of the energy and preventing penetration. The ability of the polycarbonate layer to stop projectiles with varying energy is directly proportional to its thickness,[4] and bulletproof glass of this design may be up to three inches thick.

Laminated glass layers are built from glass sheets bonded together with polyvinyl butyral, polyurethane or ethylene-vinyl acetate. This design has been in regular use on combat vehicles since World War II; it is typically thick and is usually extremely heavy.[5

Test standards

Bullet-resistant materials are usually tested by using a gun to fire a projectile from a set distance into the material in a set pattern. Levels of protection are based on the ability of the target to stop a specific type of projectile traveling at a specific speed. Experiments suggest that polycarbonate fails at lower velocities with regular shaped projectiles compared to irregular ones (like fragments), so that testing with regular shaped projectiles probably gives a conservative estimate of its resistance.[7] When projectiles do not penetrate, the depth of the dent left by the impact can be measured and related to the projectile’s velocity and thickness of the material.[8] Some researchers have developed mathematical models based on results of this kind of testing to help them design bulletproof glass to resist specific anticipated threats.[9]

Well known standards for categorizing ballistic resistance include the following:

Summary of Euronational (EN) 1063 test conditions in English

Summary of Underwriter’s Laboratory (UL) ballistic resistance test conditions in English

U.S. Department of Defense specifications for purchase of transparent armor – includes standards for bullet resistance (ATPD 2352P).

U.S. National Insititute of Justice (NIJ) standard for ballistic resistant protective materials (NIJ Standard 0108.01).

Environmental effectsThe properties of bullet-resistant glass can be affected by temperature and by exposure to solvents or UV radiation, usually from sunlight. If the polycarbonate layer is below a glass layer, it has some protection from UV radiation due to the glass and bonding layer. Also, over time the polycarbonate becomes more brittle because it is an amorphous polymer (which is necessary for it to be transparent) that moves toward thermodynamic equilibrium.[10]

Impact of polycarbonate by a projectile at temperatures below −7 °C sometimes creates spall, pieces of polycarbonate that are broken off and become projectiles themselves. Experiments have demonstrated that the size of the spall is related to the thickness of the laminate rather than the size of the projectile. The spall starts in surface flaws caused by bending of the inner, polycarbonate layer and the cracks move “backwards” through to the impact surface. It has been suggested that a second inner layer of polycarbonate may effectively resist penetration by the spall.[11]

Recent advancesU.S. military researchers are developing a new class of transparent armor incorporating aluminum oxynitride (Trade name: ALON) as the outside "strike plate" layer. It is much lighter and performs much better than traditional glass/polymer laminates. Aluminum oxynitride "glass" can defeat threats like the .50 caliber armor piercing rounds using material that is not prohibitively heavy.[12] Various types of other materials which closely resemble glass are also being developed.

Spinel ceramicsCertain types of ceramic spinel (a class of mineral) can also be used for transparent armor due to their properties of increased density and hardness when compared to traditional glass. These new types of synthetic ceramic transparent armors can allow for thinner armor with equivalent stopping power to traditional laminated glass.[13]

See alsoTransparent Armor Gun Shield (TAGS

Prince Rupert's Drops

References1.^ Bertino, AJ, Bertino PN, Forensic Science: Fundamentals and Investigations, Cengage Learning, 2008, p. 407

2.^ Air Force testing new transparent armor Laura Lundin, Air Force Research Laboratory Public Affairs. October 17, 2005. Last accessed November 9, 2006

3.^ Walley SM, Field JE, Blair PW, Milford AJ. The effect of temperature on the impact behaviour of glass/polycarbonate laminates.Int J Impact Engineering 30:31–52, 2004.

4.^ Gunnarsson CA, et al., Deformation and failure of polycarbonate during impact as a function of thickness. Proceedings of the Society for Experimental Mechanics (SEM) Annual Conference, June 1–4, 2009, Albuquerque New Mexico, USA

5.^ Shah, Q. H.

6.^ Company specifications from Total Security Solutions and/or Pacific Bulletproof, accessed 9 May 2011

7.^ Chandall D, Chrysler J. A numerical analysis of the ballistic performance of a 6.35 mm transparent polycarbonate plate. Defence Research Establishment, Valcartier, Quebec, Canada. DREV-TM-9834, 1998.

8.^ Gunnarsson, C.A., Ziemski, B., Weeressoriya T, Moy, P. Deformation and Failure of Polycarbonate during Impact as a Function of Thickness. Proceedings of the SEM Annual Conference June 1–4, 2009, Albuquerque New Mexico USA

9.^ Cros PE, Rota L, Cottenot CE, Schirrer R, Fond C. Experimental and numerical analysis of the impact behaviour of polycarbonate and polyurethane liner.J Phys IV, France 10:Pr9-671 – Pr9-676, 2000.

10.^ Walley SM, Field JE, Blair PW, Milford AJ. The effect of temperature on the impact behaviour of glass/polycarbonate laminates. Int J Impact Engineering 30:31–52, 2004.

11.^ Walley SM, Field JE, Blair PW, Milford AJ. The effect of temperature on the impact behaviour of glass/polycarbonate laminates. Int J Impact Engineering 30:31–52, 2004.

12.^ Air Force testing new transparent armor Laura Lundin, Air Force Research Laboratory Public Affairs. October 17, 2005. Last accessed November 9, 2006.