Osram Opto Semiconductors GmbH of Regensburg, Germany has launched two new high-power versions of its Ostar Projection LED that offer such high luminous flux that they can be used in office projectors with brightness levels of up to 1700 lumens.

The firm says that, due to their optimized design, they offer very high luminous flux from the available chip surface. Between 1000 and 8300 lumens can be produced, depending on the color and the version (two- or four-chip) used. An anti-reflection coated glass cover instead of the usual lens, together with external optics, ensures that the light is very well bundled. The new LEDs are matched to various additional optics for highly efficient light output.

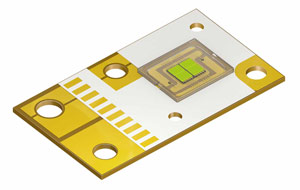

At the heart of the LEDs is a 2mm2 high-current chip based on thin-film and UX:3 technologies. The two new versions of the Ostar Projection contain two chips (P1W) or four chips (P2W) with a total luminous area of 4mm2 (1.5mm x 2.6mm) and 8mm2 (2.6mm x 3.2mm), respectively.

Picture: Osram's Ostar Projection LED.

In LED projectors, three LEDs in the colors red, green and blue serve as the light source. The LEDs are pulsed one after the other (color sequential mode), making the color filter wheel used in classic lamp projectors unnecessary. The high output of the new LEDs comes from the latest chip technologies and Osram's C2 ceramic conversion technology for a particularly efficient green. While the P1W version emits light pulses with typical brightnesses of 500lm, 1250lm and 4150lm for blue, red and green (at maximum pulse current) respectively, the P2W version emits light pulses with typical brightnesses of 1000, 2500 and 8300 lumens for blue, red and green. These high brightness levels require maximum current pulses (240Hz, 50% d.c.) of up to 12A for red and 16A for green and blue for the P1W and up to 24A for red and 32A for green and blue (8A per chip) for the P2W, as well as optimized product design to efficiently remove the resulting heat.

"To apply this high current, the four high-power chips of the P2W are connected in parallel," says Andrew Lin, LED product marketing manager. "Only then do the new Osram Ostar Projection LEDs generate their maximum brightness from the chips and turn into real power packs for large imagers," he adds. "This really opens up the use of LED projectors in offices and classrooms."

Osram says that its Ostar Projection LED enables light to be routed as efficiently as possible through the optical system, which is restricted by the etendue (which describes the relationship between the emitting light surface and the projected light surface, and characterizes how 'spread out' the light is in area and angle). The etendue of these LEDs is retained, producing an image with the same etendue as the source and, in conjunction with external optics, an extremely narrow beam of light is produced, says the firm.

To keep the thermal resistance and, therefore, the temperature rise of the LEDs at an extremely low level, the chips are placed directly on a copper plate (and not in a classic LED package) and screwed down to improve the connection with the heat-sink. Thermal resistance (Rth) is 1.1K/W for the P1W and 0.7K/W for the P2W. For both versions, the package size is 27mm x 16mm x 2.1mm.

The two new Ostar Projection LEDs will be premiered at Osram Opto's suite in the Las Vegas Hotel (#12-121) at the International CES show 2014 in Las Vegas (7-10 January). Volume production is due to start in March 2014.