The Insulating Glass Manufacturers Alliance will be releasing a new document to assist the industry in providing the proper technical procedures for multiple-cavity insulating glass units. The document is titled Design Considerations for Multiple-Cavity Insulating Glass Units. IGMA has recognized that the demand for increasingly energy-efficient fenestration products continues to rise. One method for addressing this demand is to increase the number of cavities in an IG unit. This method, while effective, can create new challenges. The guidelines presented in the document are therefore intended to assist those who design, specify, manufacture and install insulating glass units.

The purpose of this document is to guide the design, fabrication and use of multiple-cavity IG within the fenestration industry. The document is not intended to duplicate pre-existing guidelines for single-cavity IG. Rather, it is meant to expand upon those guidelines where requirements for multiple-cavity IG differ from those of single-cavity IG.

These guidelines have been developed from the collective experiences of insulating glass manufacturers, glass and glazing material suppliers, contract glaziers, design engineers, industry consultants, and persons experienced in successful IG manufacturing. The document will reflect existing technology and be subject to periodic review and change when new technologies become available, as is the normal process in IGMA.

The document will contain various sections to cover the scope, reference documents, terminology, and design considerations. Under the design considerations section, many of the important technical issues are covered, including altitude limits, coatings, condensation, fabrication techniques, gas filling, glass thickness effects, non-structural intermediate layers, optical considerations, structural applications, thermal stress and wind loads.

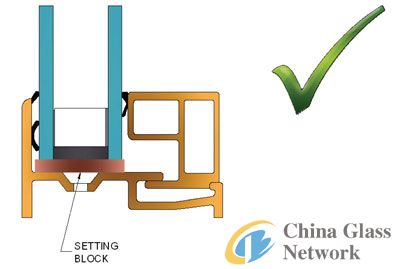

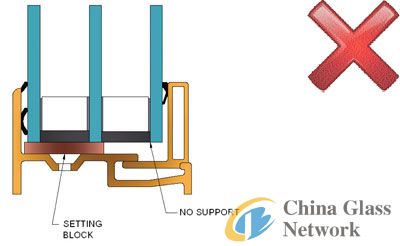

The following two figures show an example of a frame arrangement and setting block condition that is designed for a single-cavity IGU but neglects proper support for the third lite of a two-cavity or triple IGU.

Another example of the difference in single-cavity and multiple-cavity units is the response to temperature changes and air pressure differentials. Multiple-cavity units experience greater bending stress in the glass, larger lite deflection and higher edge seal pressures for the given lite and cavity thicknesses than would be experienced in a single-cavity unit. The lite deflections will be greater from resulting changes in temperature and atmospheric pressure and will be noticed more so in thinner glass and larger unit sizes. It is also known that small units with thick glass and large aspect ratios will experience exceptionally high edge seal pressures and even more so when the cavities are large. These conditions may have a tendency to have an adverse effect on the seal integrity and hence the long-term performance of the unit.

Other examples of negative performance conditions will be experienced when asymmetric glass thicknesses are used on the exterior lite or when laminated glass is used because of the glass deflection differences due to the stiffness differences of the glass lites. The conditions that relate to a thinner centre lite and different cavity temperatures may present uneven pressures on the inner and outer lites that cause different values of deflection. The presence of different cavity sizes may cause asymmetric stresses on the glass lites as well as the IG unit seals.