There are three hot topics in the packaging world. The first one is the dispensing cap, which we find mainly on top of a water bottle for inserting a certain dose of vitamins. It is a packaging format which over the last years attracted an increasing number of beverage companies, but now moves to other applications.

The second hot item is the self-heating packaging, up till now concentrated around coffee and tea beverage cans and more recently soup, but is moving to the solid food segment of the on-the-go market. And the third hot item in packaging, which of course is the convenience of the on-the-go packaging, a fast growing market segment which spreads wider and wider from ready-to-eat meals and lunch snacks into convenience packaging for outdoor activities.

It is interesting to see all these three topics combined in one innovation.

This new innovation solves the inconvenience to feed babies and toddlers with a milk powder baby formula when on-the-go. Although the market has seen interesting innovations in packaging for this type of product, all of them maintained the "wrestling" of the parents with a box of powder, a measurement spoon, a baby bottle and a nipple, after which (sometimes painful) wrestling the parents on-the-go have to look for a heating facility, before finally the baby can enjoy its "meal".

The answer comes in the form of a self-heating packaging, including a milk powder dispenser, the necessary spring water and a baby nipple. The new innovative packaging is developed by Dutch start-up Aestech in Eindhoven and is a self-heating packaging for semi-liquid food, particularly baby food.

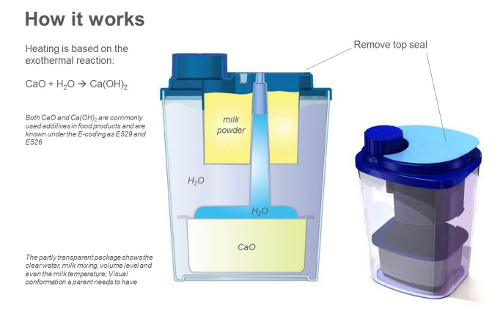

Contrary to existing self-heating packaging, mainly metal beverage cans with pre-mixed coffee or tea, this self-heater has a separate chamber/dispenser in which the milk powder is stored, while the heating-element is located at the bottom of the largest chamber, which holds the spring water.

In other words it isn't a pre-mixed product as the ingredients (vitamins and milk powder), are stored separately from the spring water, staying dry till the moment of consumption, maintaining the "power" of the supplements.

The heating element

To be sure that the heating element is fully surrounded by the to-be-heated liquid (the bottom as well), the heating element, made from aluminum, is standing on small columns. This is of utmost importance, not only to guarantee the best possible heat transfer, but also to prevent the heating element with its sometimes brusque exothermal reaction to melt through the bottom of the plastic packaging.

This design is a deviation of the common practice with the self-heating beverage cans, where the heating element is an integrated part of the bottom of the packaging and where the activating button, consequently, also is located. In the Aestech design the activating button is at the top of the packaging and the heating element is separated from the bottom by free-flowing liquid.

Of course the baby formula application in this is of importance as much less energy is needed to bring the milk product to the correct temperature of 37°C (100°F), in contrast to the roughly 62°C (143°F) for coffee.

The construction

The packaging consists of four compartments or chambers. The top compartment (or dispensing chamber) with the activation button holds the dry matter (milk powder and vitamins) and is sealed airtight with a foil. The space between the dispensing chamber and the heating element is the compartment which holds the to-be-heated liquid, in this case spring water.

The heating element is fully immersed in the to-be-heated liquid to guarantee an intensive contact between the liquid and the element and to prevent a direct contact with the heating element by the consumer.

The heating element itself is filled with a certain quantity of calcium oxide that thermally reacts with water to calcium hydroxide heating up the element. The water needed for this exothermal reaction is located in the tube, which runs from the heating element to the activating button at the top of the packaging.

How it works

After removing the cover seal, the activating button can be engaged through which the film seal between the powder dispensing chamber and the compartment holding the spring water will rupture and the dry matter (milk powder) will drop into the compartment below, which holds the drinking water.

By pushing the above said activation button a second action will occur simultaneously as the pressure will push the water in the tube into the heating element. Consequently an exothermal reaction with the calcium oxide will take place. The heating element heats up and the heat is transferred to the milk powder/water mix around the heating element.

After approx. 2 minutes and a bit shaking of the packaging the baby formula has reached the appropriate temperature of 37°C (100°F), the nipple can be put in place and the baby or toddler can enjoy its meal.