Tokyo-based Mitsubishi Electric Corp says that it has begun shipping three new types of silicon carbide (SiC) power module for home appliances, industrial equipment and railcar traction systems. The modules, which use Schottky barrier diodes (SBDs) made with SiC, are expected to reduce the size, lower the weight and raise the efficiency of inverters in power electronics devices.

The hybrid SiC DIPPFC (dual-in-line package power-factor correction) – a transfer-mold-type IPM (intelligent power module) with for PFC circuits - for home appliances, together with a hybrid SiC-IPM for general industry applications and a hybrid SiC module for railcar traction systems, are being exhibited at the Power Conversion Intelligent Motion Europe (PCIM Europe 2013) event in Nuremberg, Germany (14-16 May).

Mitsubishi Electric says that, in recent years, inverters have come to be used in a wide variety of applications, including home appliances (such as air conditioners and refrigerators) as well as industrial equipment and railcar traction systems. Power semiconductors using SiC can dramatically decrease power loss and enable high-speed switching, which is raising expectations from the point of view of energy efficiency, the firm adds.

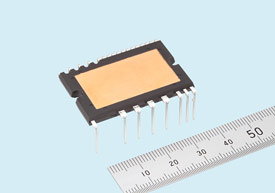

Picture: SiC DIPPFC for home appliances.

In the PSH20L91B6-A hybrid SiC DIPPFC for home appliances, SiC-SBDs reduce the recovery current and decrease electromagnetic interference (EMI) noise. Rated for a voltage of 600V and current of 20Arms, the module realizes high-frequency switching of up to 30kHz. With under-voltage, over-current and over-temperature protection, the PFC circuit and built-in drive IC reduce the footprint and simplify the wiring pattern (using interleave connection). The package dimensions (24mm × 38mm) are compatible with Mitsubishi Electric’s supermini DIPIPM products.

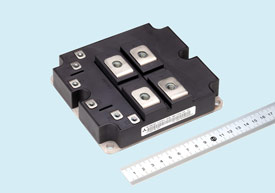

Picture: Hybrid SiC-IPM for industrial equipment.

The PMH200CS1D060 hybrid SiC-IPM for general industry reduces power loss by about 20% compared to Mitsubishi Electric’s PM200CS1D060 (S1-IPM) device and enables smaller, more efficient equipment. With 6in1 connection, the 50mm × 120mm package and control terminals are compatible with Mitsubishi Electric’s PM200CS1D060 (S1-IPM) module. Rated for 600V and 200A, under-voltage, over-current and over-temperature protection (including an on-chip temperature sensor) are the same as those in Mitsubishi Electric’s PM200CS1D060 (S1-IPM) module.

Picture: Hybrid SiC Modules for railcar traction system.

The CMH1200DC-34S hybrid SiC module for traction systems (which is rated for 1700V and 1200A) reduces power loss by about 30% compared with Mitsubishi Electric’s silicon-based CM1200DC-34N (N-series IGBT) device and enables more efficient devices. With 2in1 connection, the 140mm × 130mm package and terminals are compatible with Mitsubishi Electric’s CM1200DC-34N (N-series IGBT). High reliability makes the module suitable for use in traction systems, says the firm.

Mitsubishi Electric adds that the new SiC modules are compliant with RoHS (European Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment).