Start to look into LED lighting and quickly it becomes obvious that one type of LED will not suit all situations.

After a while, you get sophisticated enough to take colour-rendering index (CRI) and colour temperature into account, and even then you are only about halfway down the check list.

A little colour science

There is no scientific definition of white light because, like beauty, white is in the eye of the beholder.

However, everybody agrees that daylight is white, or at least a type of white, and daylight comes from the sun - a ball of gas with a surface temperature about 6,500 Kelvin.

Nobbs is head of colour physics at a unique institution: Leeds' department of colour science, which was established in the 1880s to support textile dying - a regional speciality at the time.

Black-body radiation is the electromagnetic radiation that is emitted by a perfectly non-reflective object - hence 'black' - at any particular temperature.

At low temperature it has only long wavelengths, to which decreasingly short wavelengths are added as its temperature rises.

A horseshoe in a furnace gets red-hot, then white-hot as yellow green and blue get added to the red in its spectrum. If you could get it to 6,500K, it would emit something like sunlight.

Daylight is not quite sunlight, but a mixture of slightly yellow-ish sunlight and the blue of the sky, said Nobbs.

It has a continuous spectrum across the 750nm (deep red) to 380nm (violet) we see in a rainbow.

And then the brain gets involved

Humans do not have constant colour sensitivity across this band.

Instead the eye has four different types sensors.

Three have overlapping sensitivity bands centred on red green and blue.

The fourth is for night vision and plays no part in colour vision. Its sensitivity peaks close to 500nm and its output is perceived only as shades of grey.

Although the colours of the rainbow have two ends, the brain happily wraps these into a perceived loop.

"Read meets blue psychologically," said Nobbs, "there is no jump, it goes red-purple-blue."

Based on human perception of all viewable colours, in the early 1900s American painter Professor Albert Munsell developed the colour classification system that is still used today.

He spotted that any particular colour has three characteristics:

Hue - the colour of the rainbow

Lightness - how grey and dark the colour is

Intensity (chroma) - how washed out the colour is. Pastel shades have low intensity.

Munsell arranged vivid rainbow colours around the edge of a circle, red meeting purple, and put white in the middle circle's centre.

Then along lines from the centre to the vivid hues he put all of the intensities of each hue - so there is a circle of pastel shades quite near the middle.

Lastly, turning the circle into a cylinder, he put black above the central white and all greys along a vertical line between white and black. And above every hue/intensity point on the circle, its various lightnesses fading to black.

All the time that things were viewed in broad band light - the sun, candles or hot filaments, there was no argument over colours as they look the same - if a little more vivid by sun than by candle.

Then came fluorescent and arc-based light sources which do not have broad spectrum emissions.

Things could change apparent colour when transferred from filament light to fluorescent light, and so some way of quantifying the way a lamp rendered colours was needed.

Enter colour rendering index

Over the first half of the 20th century, scientists worked on ways to quantify this mixture of spectral physics and human perception, an effort which culminated in international agreement on the colour-rendering index - CRI.

It involves the appearance of eight colour samples, called R1-R8, chosen to be roughly evenly spaced around Munsell's colour circle, none of them particularly vivid or washed-out.

"They tend to be the same intensity, which is depth of colour," said Nobbs, and to get this, they differ in lightness [height in the cylinder]."

CRI can be evaluated visually or, as each of the eight colours has its spectrum defined exactly, calculated from that information and the spectrum of the light source-under-test. In practice, it is always calculated.

The visual method involves viewing the eight colour samples under daylight, then viewing them by the source-under-test.

From this work, eight 'special' colour rendering indices are declared from the differences in appearance of each sample under two types of light.

The average of the special indices is the CRI of the artificial light source.

A slight complication is the colour temperature of the measurement.

And then colour temperature

It is from the black-body radiation mentioned earlier that the concept of colour temperature comes.

If we could get our horseshoe to 2,700K - the temperature of a light bulb filament - it would be emitting a recognisable white light dominated by red which is called 'warm white'.

By the time it got to 6,500K, emission would have a lot more blue in it - a colour called 'cool white'.

Somewhere in between, is 'neutral white'.

"A 40W bulb is 2,800K, a candle is 1,900K, and a sunset is around 2,000K. People genuinely feel more comfortable under these warmer colours," said Nobbs

CRI is actually measured by first adjusting the colour temperature of the reference 'sunlight' to the effective colour temperature of the source under test.

This colour temperature is established by shining both the reference and the source-under-test on a white surface, then adjusting the reference colour temperature so that it looks most like the test source.

If this was not done, a perfect source under test would not get a perfect score (100) unless it happened to be the same colour temperature as the reference.

CRI is a good technique, with some limitations. For example, averaging allows a source to miss one sample completely and still score up to 87.

"If you have dyes and pigments with very broad characteristics, there is no problem," said Nobbs. "If you create colour by a narrow band of absorption or reflection, that is where the problems arise."

Modern vivid dyes have narrow spectrums, and sources such as 'tri-phosphor' fluorescent tube have bands in their spectrums that are narrower than CRI can cope with.

For example, said Nobbs, 'tri-phosphor' fluorescent tube is much more efficient that the broadband type it replaced - 83 lm/W compared with 65 lm/W.

It has three narrowband emitters - red green and blue - whose spectrums are carefully positioned to give a CRI of 93 - a very high figure as 'artificial daylight' sources have a CRI of 94.

But some garments that are green in daylight are brown under tri-phosphor tubes.

"So high CRI can fool," said Nobbs. "If you take traditional fluorescent warm white, it has a CRI of about 54, yet is perfectly acceptable in the domestic environment."

There are better colour systems being looked into by organisation all over the world, but none of them have international agreement yet.

When the calculated metric is plotted against people's perception of colour rendering, better systems produce less scattered plots compared with simple CRI.

However, differences are not huge, and no single index number is ever going to encapsulate everything about colour rendering.

Rise of the white LED

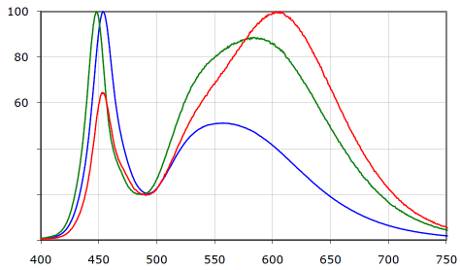

Almost all white lighting LEDs are based on a blue-emitting die with a phosphor layer on top than converts some of that blue to broadband amber.

The result appears white, even though the spectrum has a narrow blue spike and a broad hump stretching from blue to red.

Details differ, but generally cool white leds have less phosphor in the way so they are more power efficient at the expense of CRI.

Warm white LEDs have more phosphor, so more loss and less efficiency, but a higher CRI because there is less blue spike and more broad hump.

Warm white LEDs also tend to have phosphors which stretch into deep red.

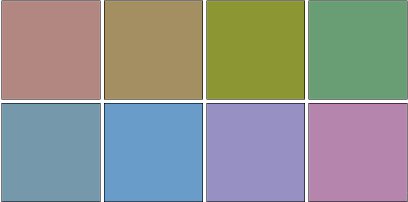

Three spectra for Cree's XR-E LEDs: for 5,000K CRI=75 (blue), 3,700K CRI-75-80 (green) and 2,600K CRI=80 (red). CRIs of 90 are possible with blue die plus amber phosphor combinations.

And here comes the first restriction of CRI with respect to white LEDs: none of the eight standard colour samples include deep red.

Adding R9

As well as R1-R8, there are seven other Munsell colour samples that are generally measured by automatic spectral test equipment: R9-R15.

These are not included in CRI, but one of them, R9, has a lot of deep red in it.

"R9 came up when LEDs were used for medical applications because people needed to see the blood," Rudi Hechfellner director of applications LED maker Lumileds told Electronics Weekly.

And it is not just medical folk that are interested.

"A good example is grocery. If you are lighting up beef with poor R9, it looks grey and not so attractive. Ketchup and pasta sauce are the same," said Paul Scheidt, marketing manager at LED maker Cree. "There are some other useful additions: R13 is a [caucasion] flesh tone."

Lumileds, Cree, and other lighting LED makers can produce R9 figures for interested parties, but do not specify them because they would have to test to that figure and where would it end? Testing all of the 100 samples in the Munsell colour circle?

Instead, LED makers publish spectrums for their products, giving customers burdened by tricky applications all of the data required to make their own evaluations and calculations.

For interior domestic lighting deep red rendering may be less important, but there is a preference for lower colour temperatures (extended red spectrums) of around 2,700K in Europe and North America, and cooler 5,000K white in Asia and parts of southern Europe.

These preferences could be historic, although some observers see another psychological link: they loosely coincide with the colour temperatures than most flatteringly illuminate native complexions.

All lighting LED makers produce a range of colour temperatures, with varying CRIs depending on the technique used to set the colour temperature.

In general, power efficiency - which is the main reason LEDs are being introduced for lighting - is good in all LEDs, but falls with reducing colour temperature: from 100-120 lm/W for the best cool whites to 70-90 for the best warm whites. These figures will rise as the technology improves.

Cree has a high CRI brand for light engines and end-products called TrueWhite.

"TrueWhite specifically refers to a technology. It uses a greenish-white from BSY [blue + saturated yellow] LEDs, mixed with red from red-emitting LEDs," said Cree's Scheidt. "It is a very efficient way to create warm white colours and gives a very high CRI - over 90 - with broad spectrum as well as high red content."

Cree also produces traditional lighting LEDs using extended-red phosphors to get warm whites.

"Some are available giving 80, 85 or 90 CRI minimum," he said.

Lumileds has a twist on this traditional approach with its Lumiramic technology, using a pre-moulded sliver of yellow fluorescent ceramic instead of fluorescent paint.

This allows the colour temperature to be precisely controlled during manufacture despite natural LED die variations, as each die gets a custom-selected ceramic sliver on the production line.

Lumiramic has allowed the firm to produce its 'Luxeon A' range which simplify things for customers because there are only tiny LED to LED variations for each colour temperature band.

"We know how the independent parameters of phosphor and die behave over temperature," said Lumileds' Hechfellner. "Luxeon A is product line with CRI options from 80-90."

CRI: an obsession

For the uninitiated, the default option can be to pick a high CRI LED over one with an acceptable CRI.

Street lights are an example.

Street lighting consumes a huge amount of the power budget of developed nations, so power efficiency has always been the important metric.

For years in the UK, low-pressure sodium (LPS) lighting was the norm.

This vivid yellow technology has an incredible power efficiency that LEDs will never reach - around 300 lm/W compared with 100 lm/W for LEDs.

The yellow is virtually monochromatic and so unless you are viewing particularly ripe bananas its colour rendering index is zero.

But you can still see to drive.

LPS makes acceptable street lighting with CRI, due to the way CRI is calculated, of a minus number.

Creamy-yellow high-pressure sodium (HPS) lamps are the norm in the US and becoming so in the UK. They have efficiency from 50-150 lm/W - ripe for attack by LEDs.

And they have an appalling CRI of 25, and yet no one complains because they produce acceptable light with the bonus that you can make out a few colours.

So streetlight designers and specifyers had a choice of two, both with awful CRI.

And then along came white LEDs with a choice of CRI, all of them better than LPS and HPS.

Some get it, and some do not.

"Some customers order CRI of over 90 without really knowing what they are doing. My personal feeling is that we are chasing numbers that make no sense and are paying for it in power consumption," said Lumileds' Hechfellner. "Street lighting is one example that is highly deployed, especially in Asia. If streetlights were specified with a CRI of 70 rather than 80, we could save a nuclear power plant."

He added that the US government gets it, and its energy information website has a message saying high CRI does not necessarily mean quality of light.

On streetlights, Cree's Scheidt said there is a strong preference for 4,000K white LEDs to match the metal halide lights (70-117 lm/W, CRI=70) used in special applications like car parks where people have to recognise their vehicle.

"4,000K for street lighting is not same as 4,000K for office because CRI is not the same," he said.

So 4,000K LEDs with a CRI of 70 can be specified for car park lighting to save power, whereas LEDs with the same colour temperature, but a CRI of 80 might be more applicable in an office.

For general road lighting, Lumileds' Hechfellner thinks streetlights need more reason and less specmanship. After all, you will not have forgotten that the incumbent technology has a CRI of 25 max.

"Insurance companies and municipalities can only see numbers, numbers and not perceptions. Is the objective to make cars look good, or higher energy efficiency?" he asks. "We could see 10-15% extra energy efficiency if we went from 70 CRI to 60 CRI. We are struggling to persuade the industry."

And so?

So don't over-specify CRI if you don't need it, unless you like wasting power.

The take-away message from all three experts: Nobbs, Hechfellner and Scheidt, is that there are better systems than CRI, but none of them are dramatically better than CRI in most circumstances.

And that any system which produces a single number is going to be flawed.

The devil is in the detail and you need to understand the limitation of the technology of interest - a blue spike, amber hump and variable red in the case of white lighting LEDs; or spectral gaps with tri-phosphor fluorescents - and use metrics that applicable to your source and your application.

Avoid over-specifying warm colour temperature or CRI because you will pay for it in power.

Pick the colour temperature that your customer desires, work out the CRI that your customer needs, and then check for special spectral requirements.