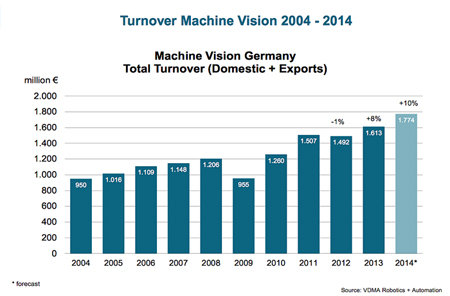

“The machine vision industry in Germany will grow in 2014 by at least 10% minimum and overall industry turnover will exceed its sales forecast of about €1.8 billion by the end of this year,” stated Dr. Olaf Munkelt, Chairman, VDMA Machine Vision Group, at the Vision expo in Stuttgart. He was presenting the German Engineering Association’s latest assessment of the national MV market.

He added, ”For 2015, we are expecting further growth despite the macroeconomic uncertainties. In short, foreign demand is increasing while domestic demand is catching up. Strong momentum from abroad is expected, in particular from Asia and the USA.”

“All over the world we are seeing strong demand for automation solutions and MV benefits as well. With the need for 100% quality checks keeping pace with production speed and highest process reliability, it would be difficult to achieve the increasing requirements of a modern production environment without machine vision,” said Munkelt.

Report highlights

China In the past few years China has been the most dynamic market for MV systems from Germany. Except for the 2009 crisis year, exports to China have risen significantly above average. Since 2008 turnover has more than quadrupled. In 2013, turnover rose by 23%, compared to 2012. With a share of now 10% in total turnover, China already ranks second after North America.

Robots Sales of industrial robots are a good indication for the level of automation and of the further development of MV turnover. According to the International Federation of Robotics (IFR), sales of industrial robots in China are expected to increase at least 25% on average per year from 2015 to 2017 reaching 100,000 units in 2017. By 2017, more than 400,000 industrial robots will be installed in the factories of China – many of which will be equipped with “Robot Vision – Made in Europe”.

Embedded Vision Even before the discussion about “Industry 4.0“came up in Germany, machine vision had been dealing with challenges that an increasingly networked production brings along. Over recent years, MV systems have been evolving from pure inspection systems to production optimizers and as embedded vision, they are now playing a key role in the production process.

Applications increasing The number of possible applications of machine vision systems will increase even more in the future due to the increasing availability of components, standardized interfaces, improved computer performance as well as shifting essential components to the Cloud.

Conclusions

Munkelt concluded, “Beyond the factory environment, embedded vision systems increasingly play a greater role. Whether in the medical technology field, in the food industry or in logistics, performance-adapted systems, often with a small form-factor, are needed to perfectly implement classical applications of machine vision like identification tasks.

"Machine vision has been conquering many new fields of application, in and outside the factory. Improved quality, greater reliability, increased safety and cost-effectiveness are benefits that are just as crucial in non-manufacturing contexts as in the realm of industrial production. In 2013, turnover of machine vision in non-industrial sectors grew by 25 percent raising the share of non-industrial applications in overall turnover to 29%.

”Intelligent traffic systems accounted for the highest share in total turnover of non-industrial applications, followed by medical technologies, logistics, postal sorting as well as safety and surveillance. Increasing standardization, simplification and intuitive user interfaces, greater efficiency, improved computer performance and miniaturization remain real growth drivers.”